What is Scalmalloy?

Scalmalloy Flight Hardware Manufacturing

As one of the world’s most revolutionary high-performance materials, Scalmalloy is used at the cutting edge of modern aerospace, and AnyShape is proud to provide components for the sector’s boldest designers. Read on to discover how our Scalmalloy parts are powering an aerospace revolution.

What is Scalmalloy?

Scalmalloy is a high-performance metal powder alloy composed of aluminium, magnesium and the rare earth material scandium. Over the last decade, 3D printed Scalmalloy components have been used to great effect in sectors from automotive to robotics. But considering that this revolutionary material was developed by APWorks – part of the Airbus group – it makes sense that it is still best-known as a vital ingredient of aerospace design.

What are the thermal properties of Scalmalloy in the aerospace sector?

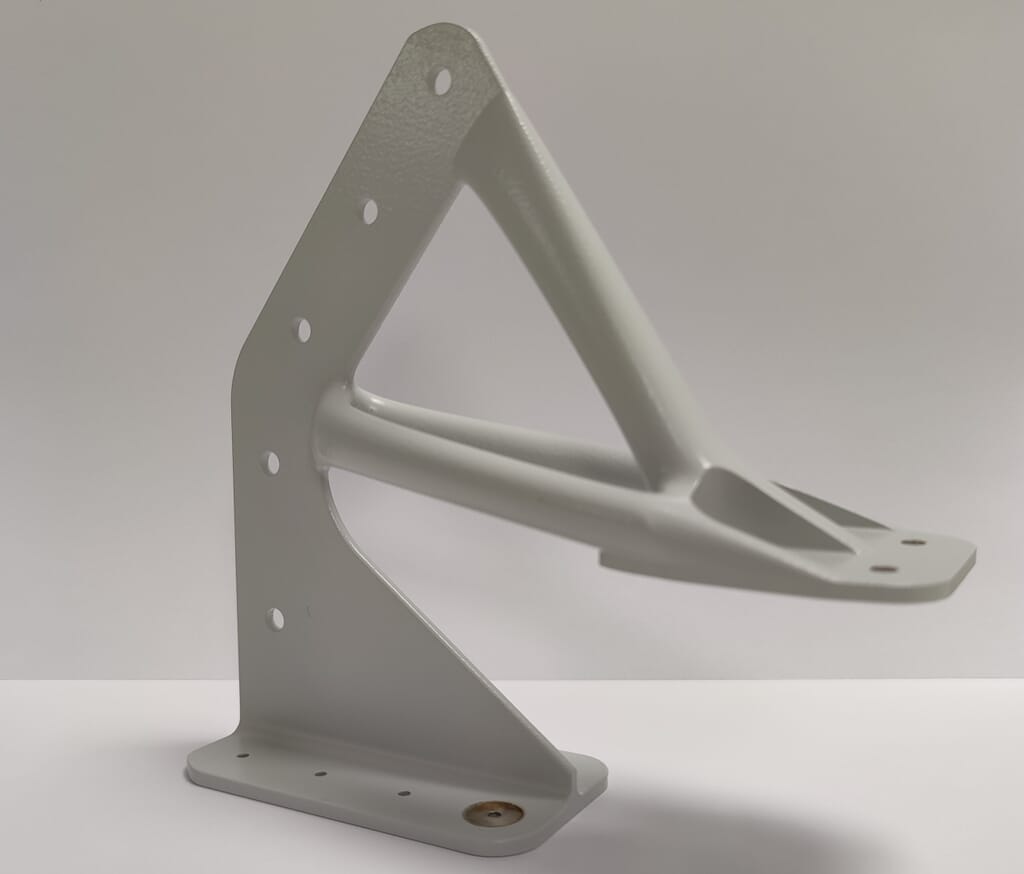

Scalmalloy is tailor-made for aerospace and meets the industry’s exacting demands. The impressive strength-to-weight ratio (Scalmalloy is as strong as titanium but light as aluminium) makes it ideal for topology optimisation tools, while its unbeatably low ‘buy-to-fly’ ratio means less weight and maximum efficiency. Add to that, Scalmalloy offers high corrosion resistance, retains its microstructure at temperatures of up to 250ºC (and is therefore highly weldable): all practical qualities for aerospace designers and engineers.

What makes AnyShape a leading provider of Scalmalloy for aerospace?

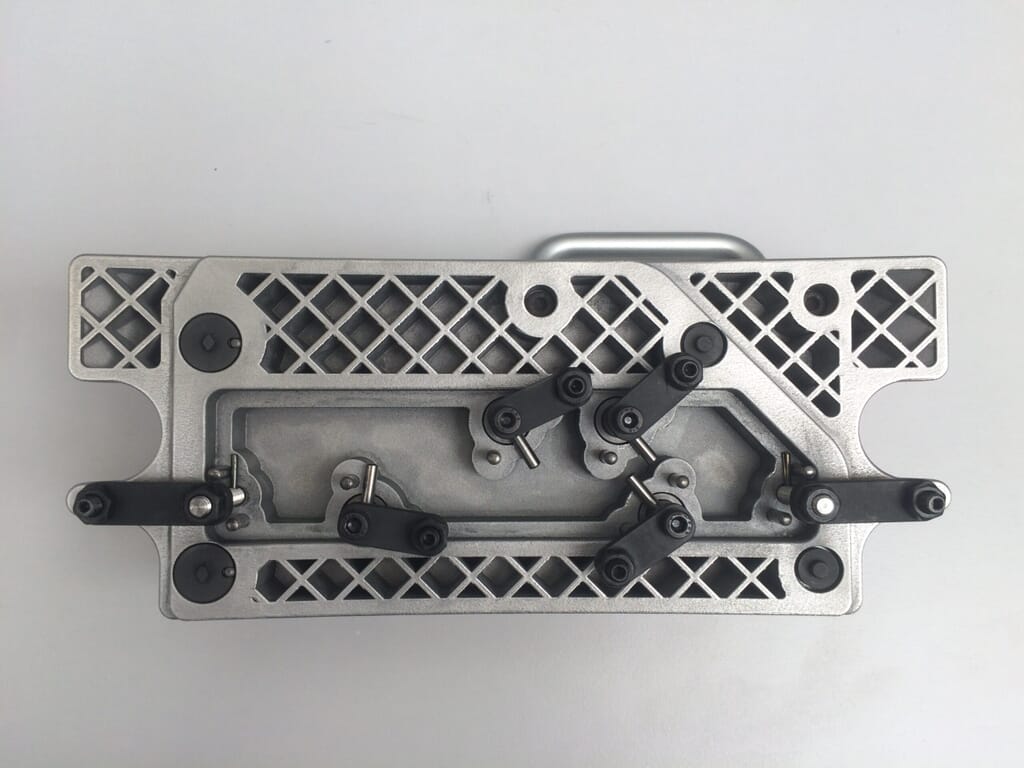

As one of only two Airbus-approved suppliers of Scalmalloy parts worldwide, AnyShape has established an enviable reputation in the aerospace industry. Today, our team is regularly commissioned by leading designers to create 3D printed Scalmalloy parts ranging from a variety of brackets to the intricate parts of robotic arms – and we expect that relationship with the aerospace sector to grow closer as the full potential of Scalmalloy becomes clear.

Clients feed back that our Scalmalloy-based components unlock a host of benefits including performance optimised design, improved fuel efficiency, reduced weight and part consolidation. You can read more about our work with additive manufacturing in the aerospace sector.

Which 3D print technologies are used to create Scalmalloy-based parts?

AnyShape has a full in-house offering of 3D print services that let us work with plastics, polymers and everything in-between. When it comes to producing Scalmalloy-based metal components, however, the key technologies used are Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS), which uses high-powered lasers and fine metal powders to produce metal parts of unmatched quality.

Of course, that’s just the start of AnyShape’s metal 3D printing service. From traditional metals – including aluminium, steel, titanium, nickel and copper – to our growing selection of custom powder materials, we’re fast becoming the first stop for aerospace and defence OEMs.

How do I learn more about AnyShape’s 3D printing service?

Our expert team is on hand to assist you. As one of Europe’s most respected AM specialists, AnyShape offers a full suite of in-house services ranging from carbon fibre 3D printing to direct metal laser sintering. Turn to AnyShape for unmatched guidance through every stage of the 3D printing process.

Get in touch with AnyShape