What Is Direct Metal Laser Sintering?

Direct Metal Laser Sintering is an additive manufacturing process that uses lasers to melt ultra-thin layers of metal powder to build a three-dimensional object.

AnyShape use DMLS to provide metal additive manufactured parts for a broad range of applications found within the aerospace, space, automotive, defence, energy, oil and gas, motorsport and medical sectors.

Why Choose Direct Metal Laser Sintering Services For Your 3D Printing Project?

There are a huge range of parts, components and assemblies that can be produced through metal additive manufacturing thanks to the wide range of high quality metal powders on offer. We regularly produce components using stainless steels, tool steels, copper, aluminium, nickel based alloys, titanium alloys, and high performance super-alloys such as ™Scalmalloy.

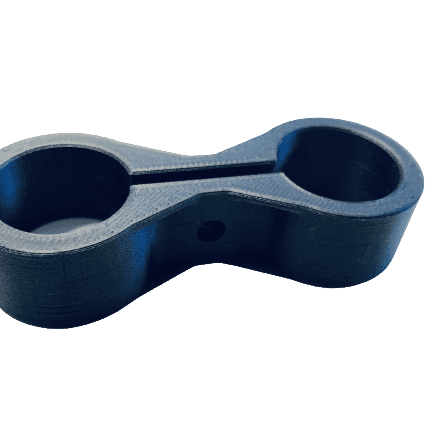

DMLS allows for highly accurate and complex structures to be created with ease. When manufacturing bespoke shapes or components rich in features, the even distribution of metal powders allows for accurate delivery on shapes as complex as honeycomb, where strength and integrity are needed at all points.

Laser sintering also provides a higher quality finish than tooled or wrought materials. The additively manufactured parts can be post machined, painted and resurfaced after development as and when required.

What can you produce with Direct Metal Laser Sintering?

DMSL is heavily used within prototyping thanks to its ability to generate detailed and complex metal components within a short time frame. Layers of metal powders are additively laser sintered one by one to produce feature rich metal components.

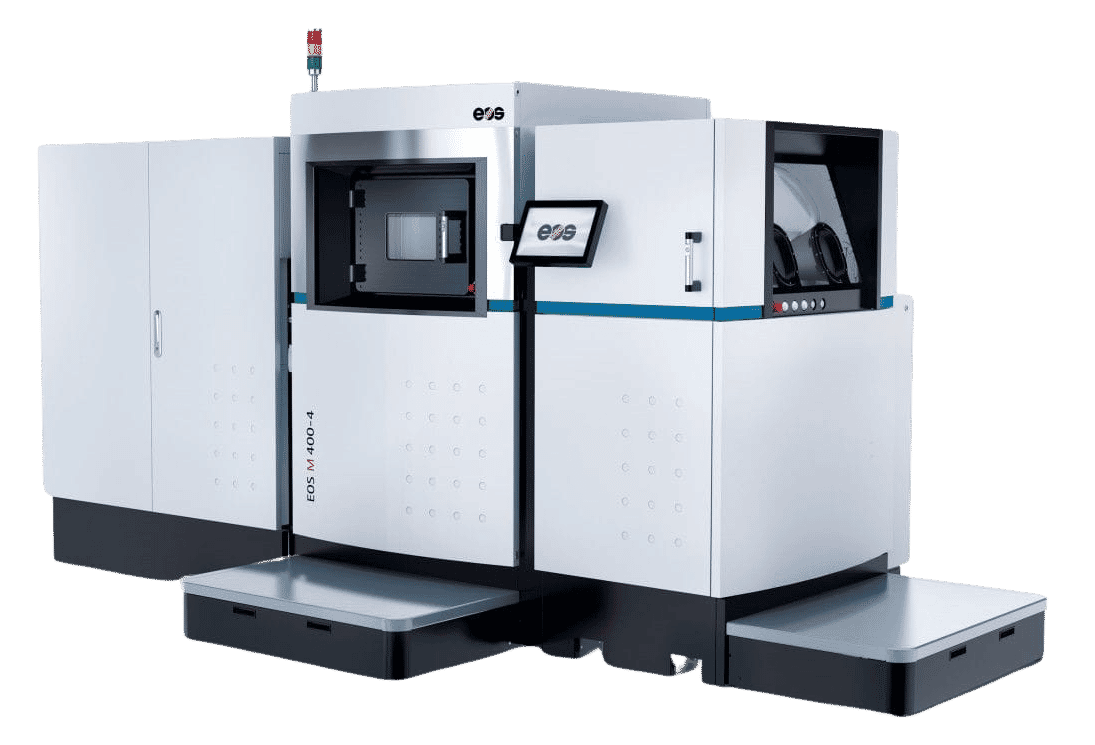

Our single laser 3D printing system utilises a powerful optic laser to mould components straight from 3D CAD drawings. Eliminating the need for any further, or time intensive, tooling. This makes DMSL a great choice for low volume and unique production parts, that are often used within aerospace and defence, automotive and the medical sectors.

You can view our technologies and download our materials data sheets below.

Our manufacturing capabilities

Trusted by engineers worldwide

AnyShape is the supplier I use the most for tooling as they lead the way in terms of both part quality and AM knowledge and capability. Over the past four years AnyShape have always met my needs and added value to all my projects