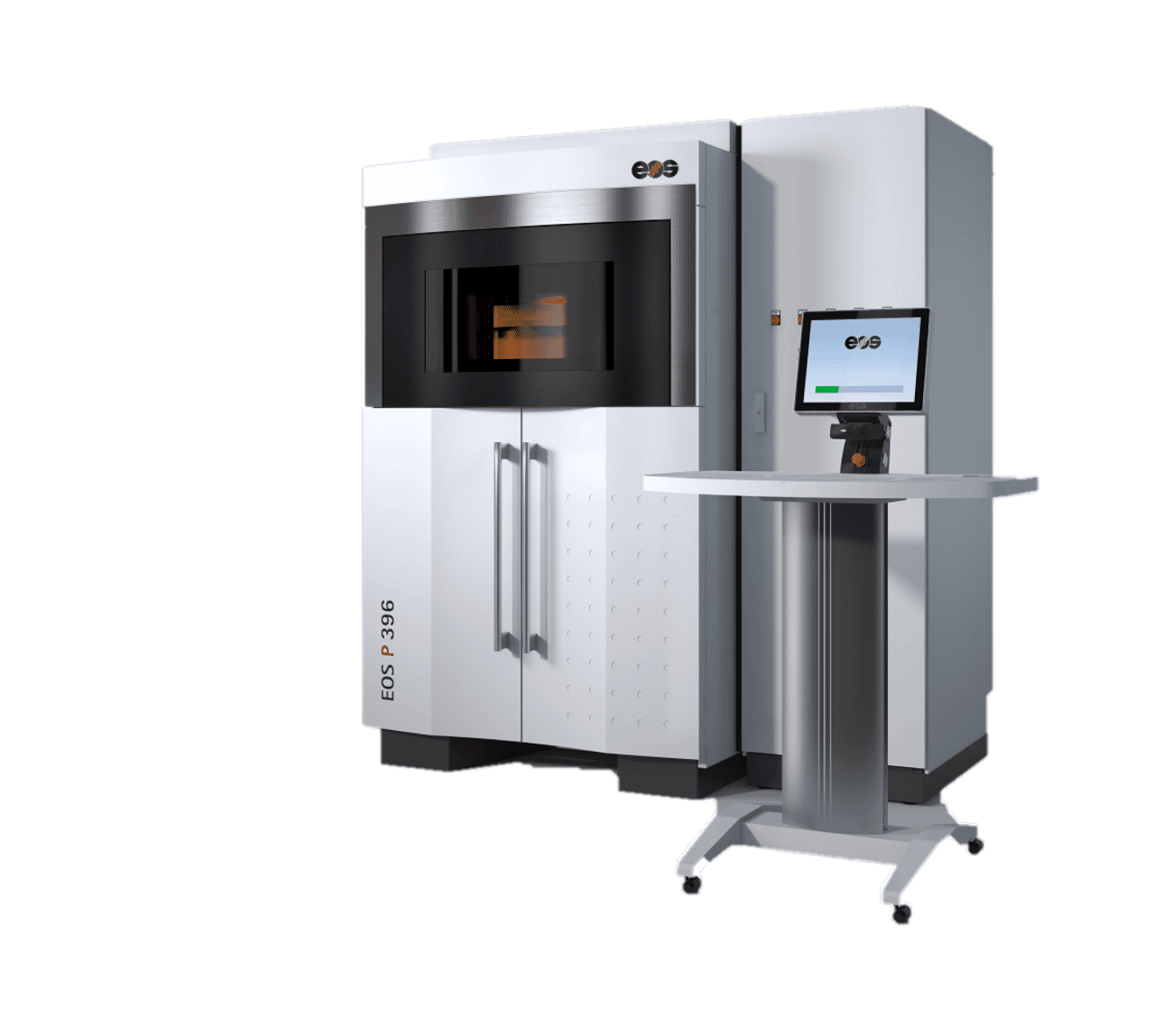

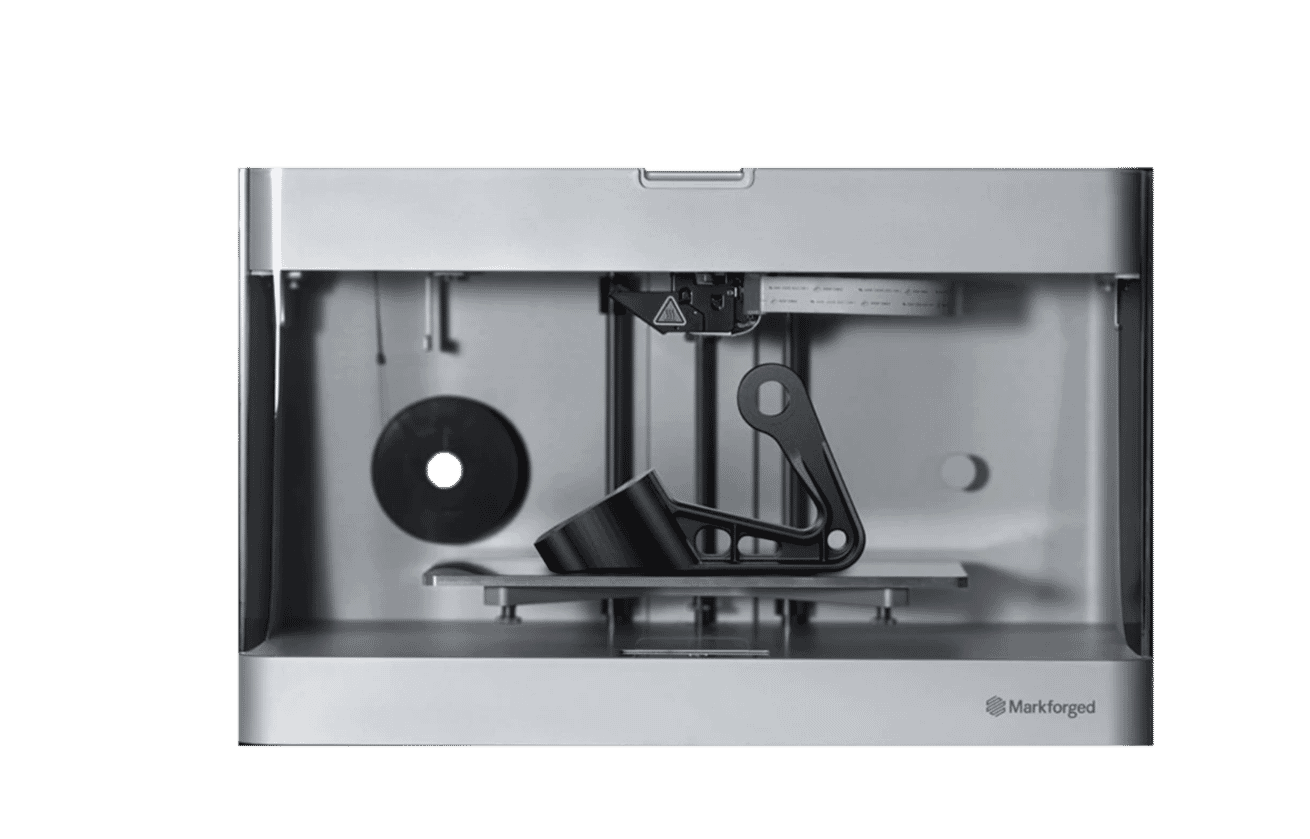

Plastic Additive Manufacturing, Selective Laser Sintering, Fused Deposition Modeling, and Continuous Fibre Fabrication

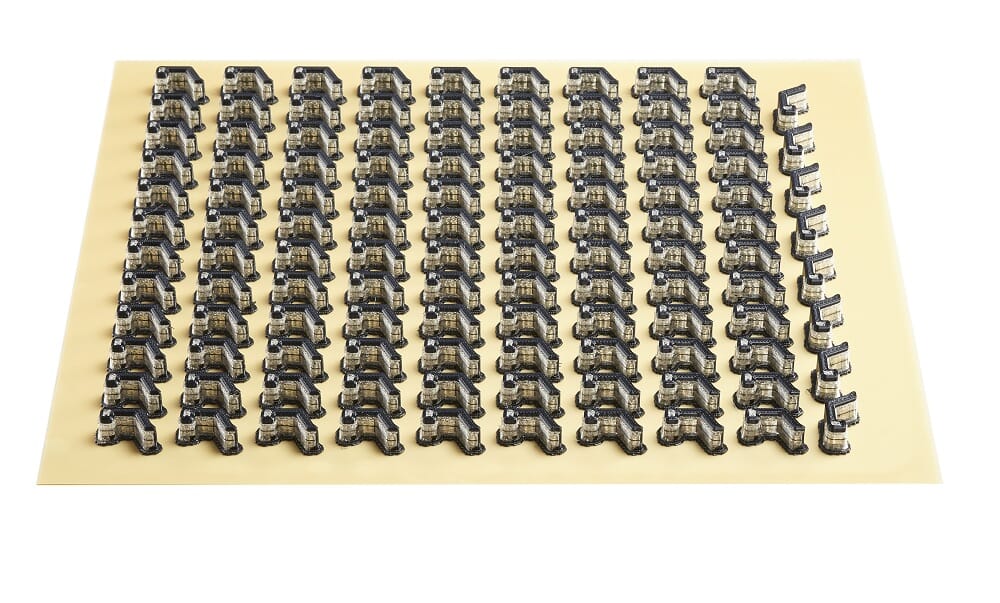

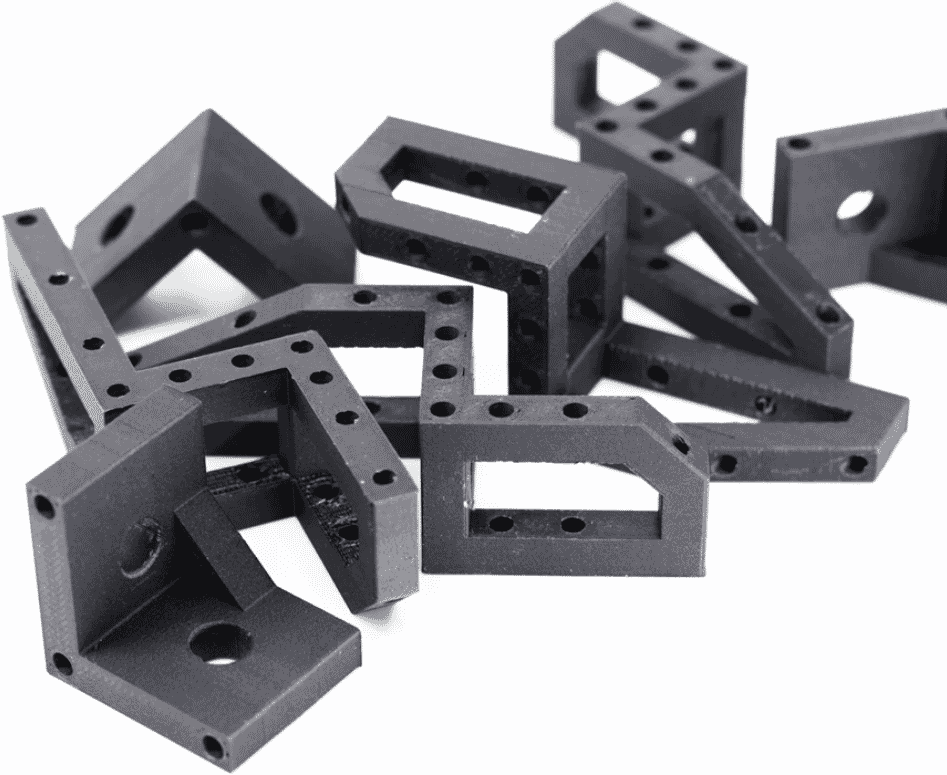

The decision as to which technology will best suit your requirements will depend on a number of factors including part geometry, intended purpose, environmental and operating conditions, material type and properties, certification or qualification requirements, features, desired surface finish, colour and quantity etc.

AnyShape can advise you along this process, help you select the most appropriate technology and material for your application and work with you to optimise your design ready for 3d additive manufacturing production. Our additive manufacturing consulting service is where it all starts, connect with an AM Expert to discuss your project or idea and benefit from years of AM knowledge and experience.

To learn more about our additive manufacturing technologies and materials, scroll through the system specifications below or click to download our range of plastic additive manufacturing materials.