From a 3D Product Mockup to a highly topology optimised rocket thruster bracket

For many years global manufacturers have used rapid prototyping as a way of creating new and innovative products and getting them to market in record time.

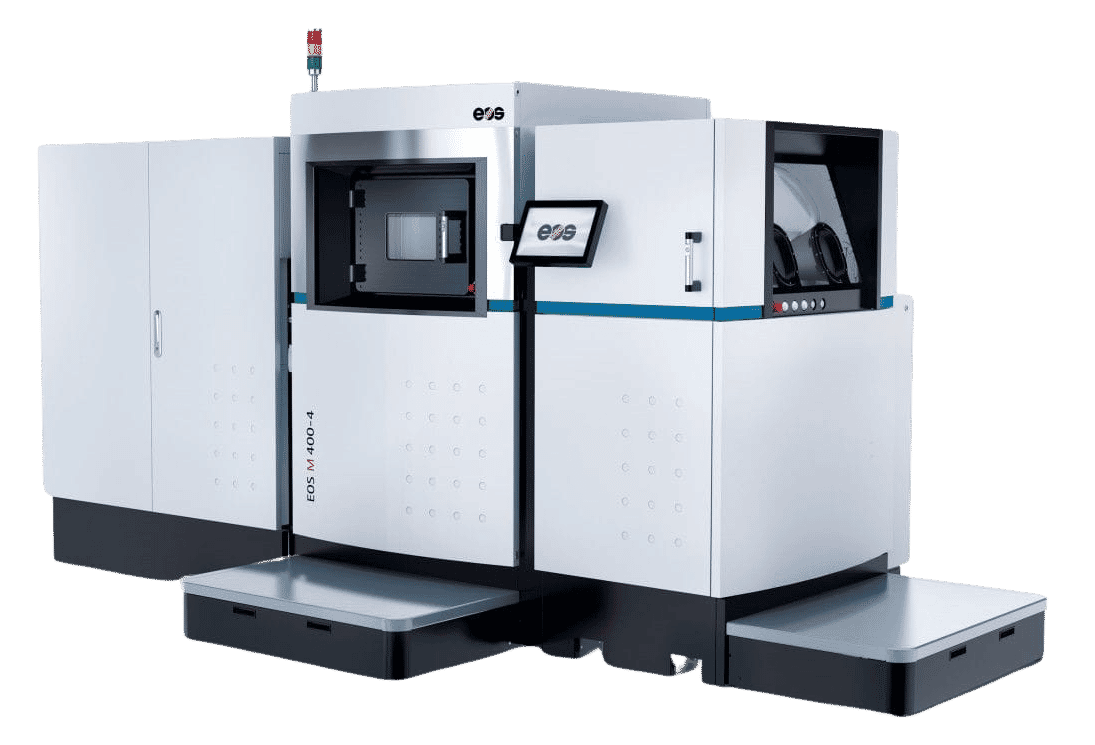

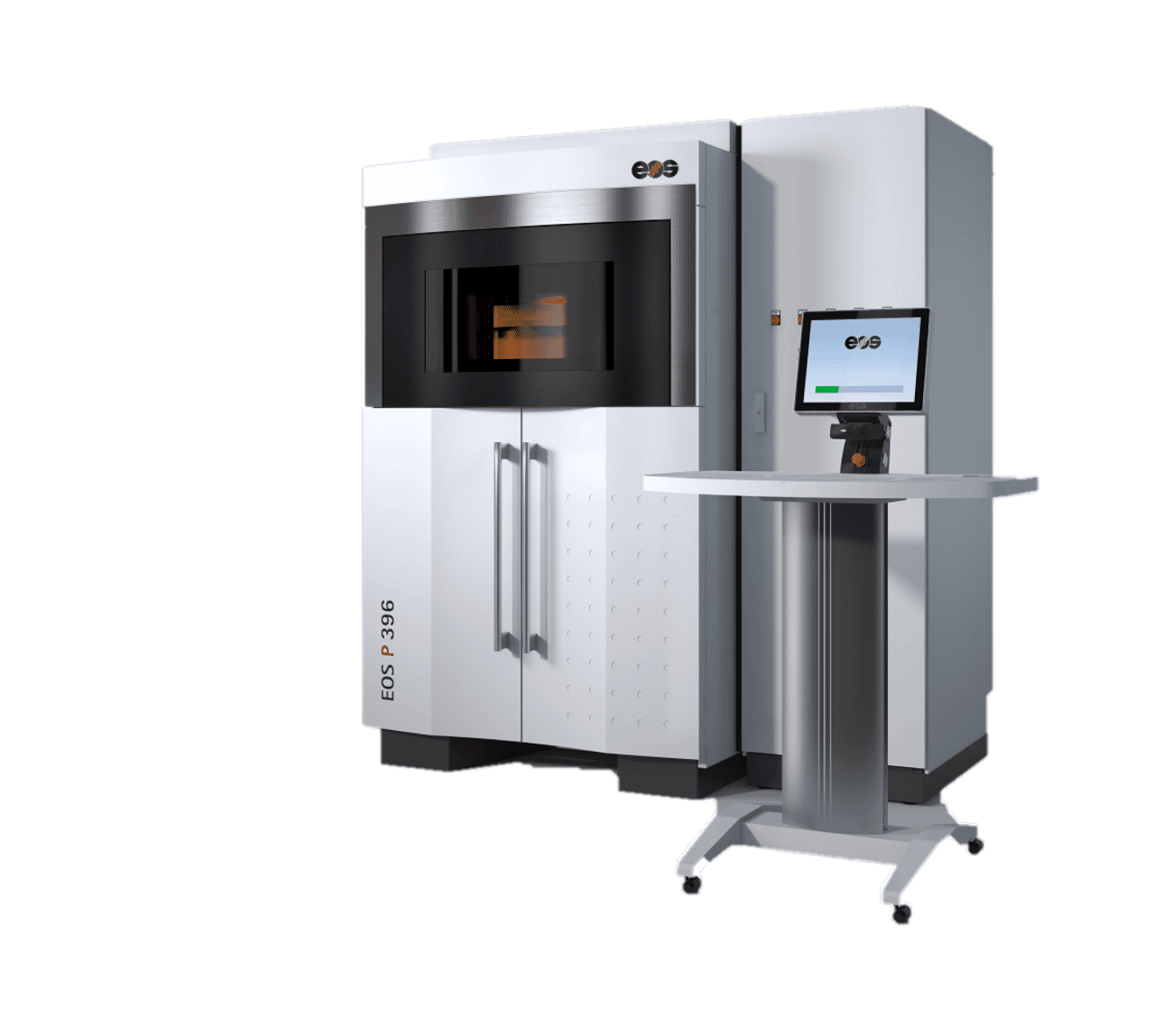

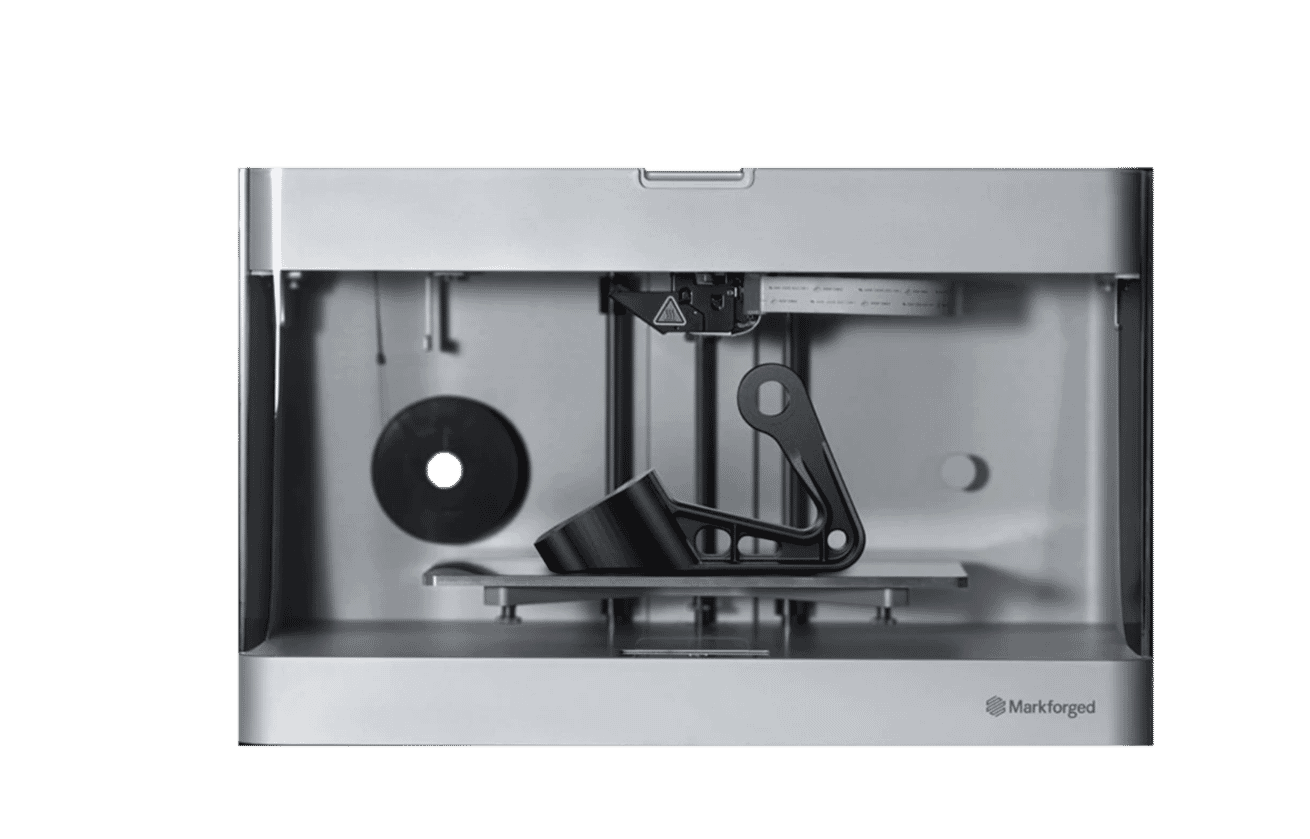

Advances in 3d printing & additive manufacturing have made this process much quicker, more efficient and more cost effective. However, innovative design and product engineers the world over understand that one 3d printing technology alone will not meet all the criteria for every project.

Whether you are looking for 3d printing plastic or 3d printed metal parts, at AnyShape we have a range of 3D printing rapid prototyping services, technologies and rapid prototyping materials at your disposal, providing you with total flexibility to choose the most appropriate technology and material to suit your needs.

Furthermore, our rapid prototyping experts are always available to offer guidance and advice to ensure your project is a complete success. From start to finish, we believe you will benefit from our comprehensive and cost effective 3d printing prototype service.

Scroll through the technologies below to see our full range of rapid prototyping capabilities and to download material datasheets for metals, plastics and composites.