What Is Additive Manufacturing?

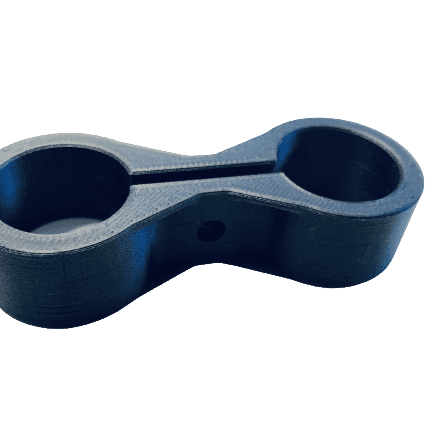

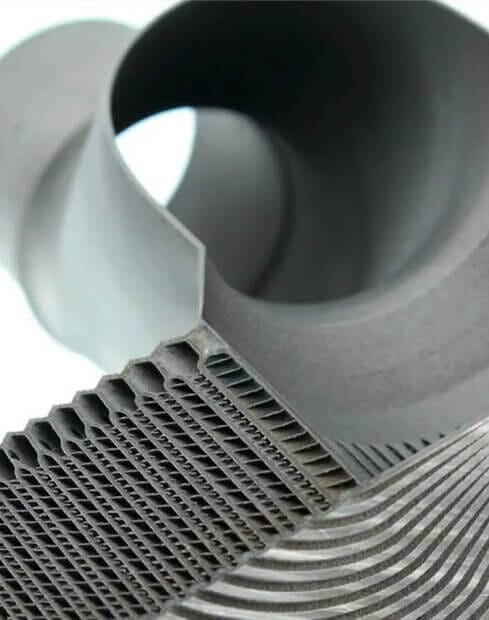

Additive Manufacturing (also called 3d printing) is a process that creates a three-dimensional object from a digital file

Additive manufacturing as the name suggests is an ‘additive’ process, compared to CNC milling which is a ‘subtractive’ process.

A design file is first generated from within CAD (computer-aided design) software. To additively manufacture the part, AnyShape’s production software will convert the design file in to slices which are then sent to the printer.

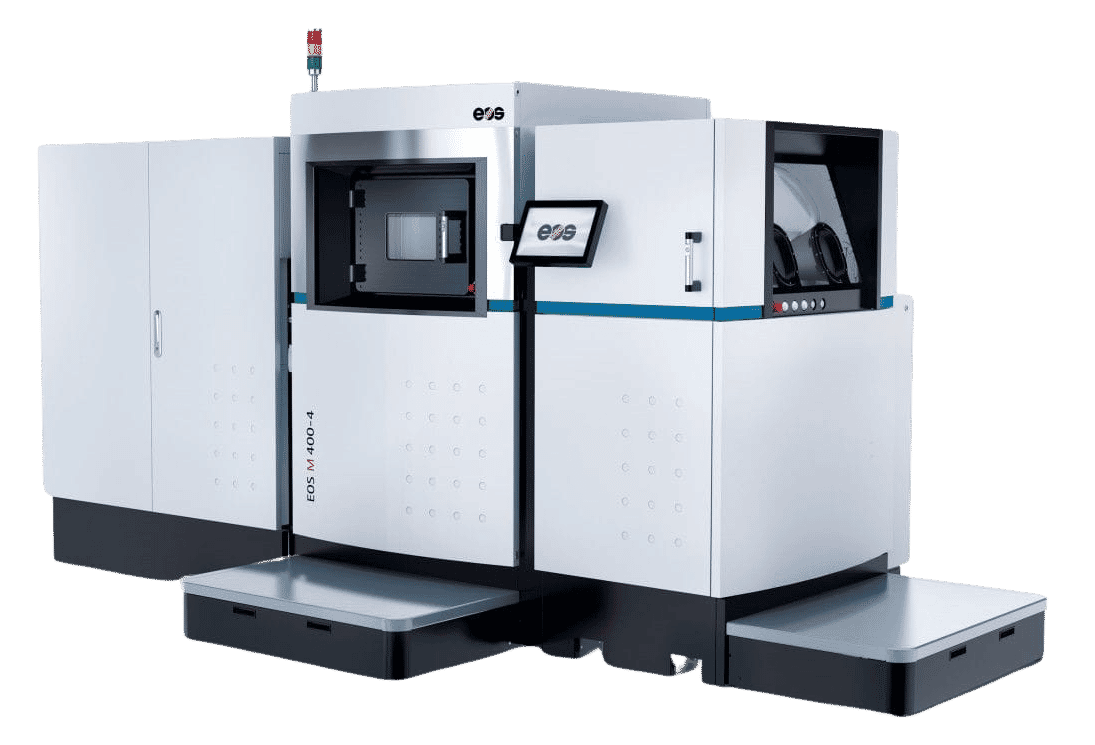

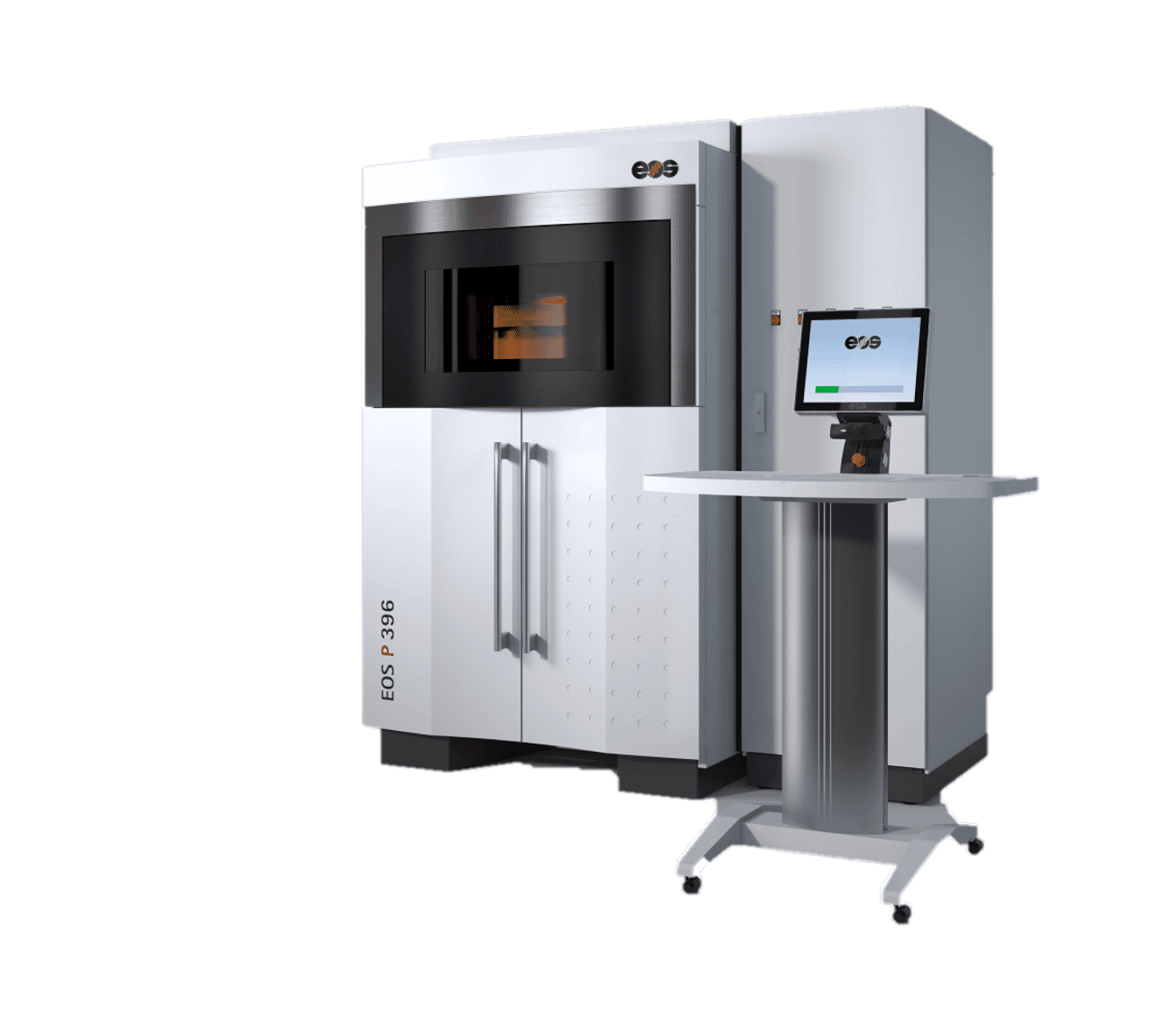

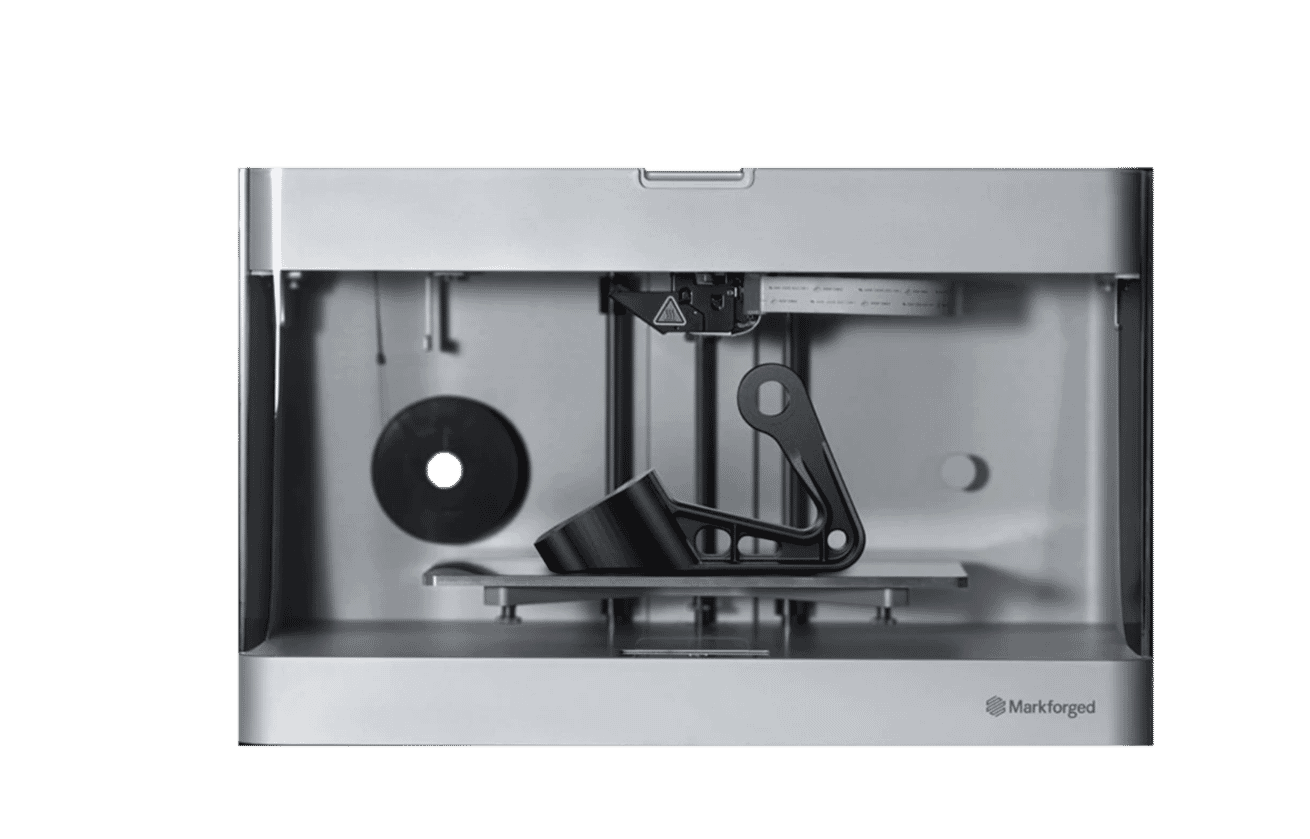

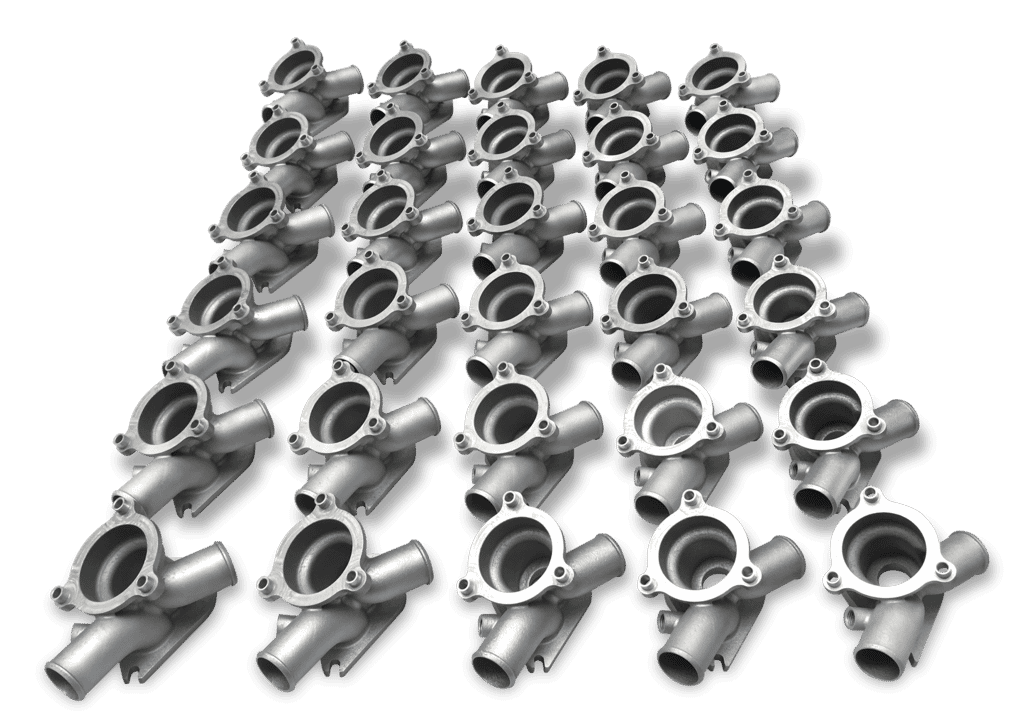

Depending on which material is chosen and the type of parts you require, AnyShape have a range of additive manufacturing technologies to meet your needs.

To learn more about our additive manufacturing services and technologies, scroll through the systems and check out the individual Technology Icons within our Capabilities section below.

You can also download Material Specification sheets for metals, plastics and composites.