In motorsport, every second counts…

Motorsport is the most competitive sport in the world; the difference of a gram can mean a second, and a second is the difference between winning and losing.

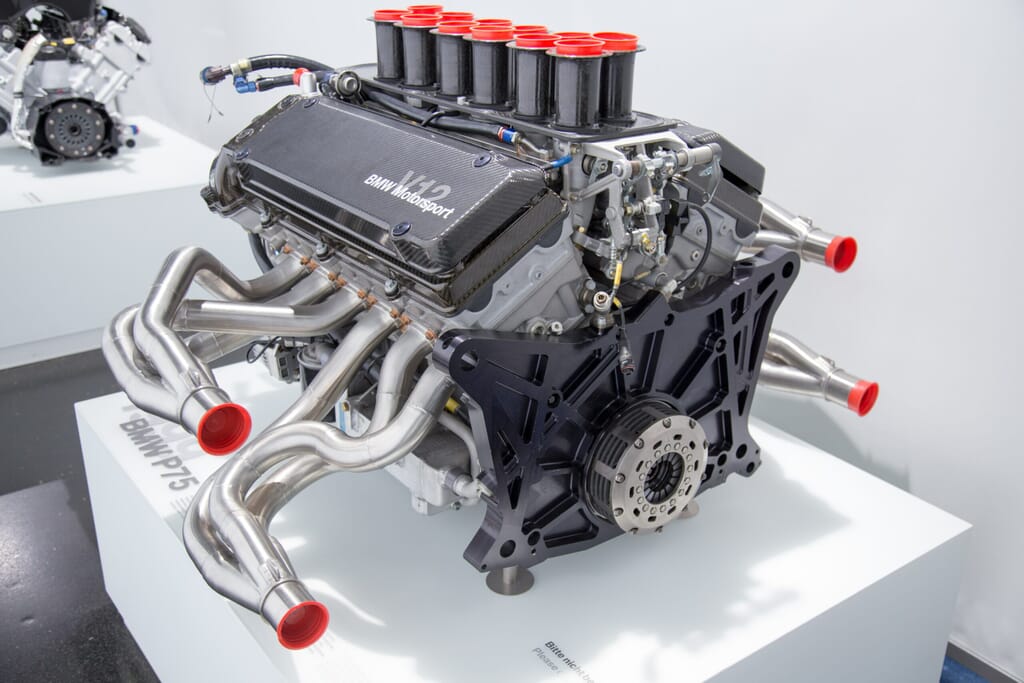

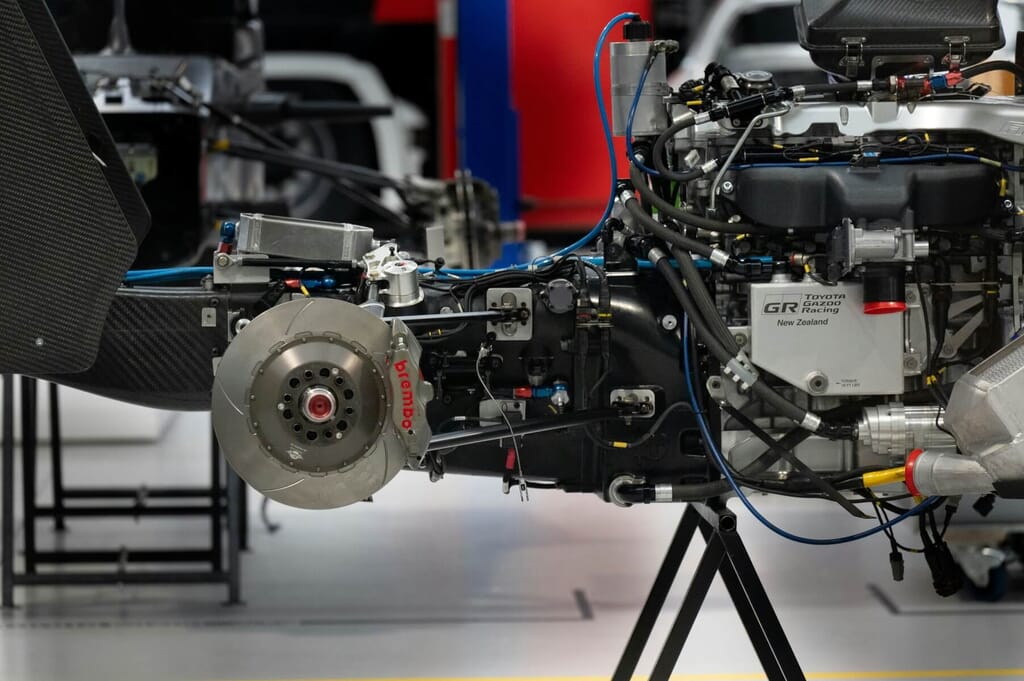

In the competitive world of motorsport, every gram of weight matters and every gram of weight shed can make all the difference. With the wide adoption of motorsport 3d printing parts now firmly established amongst automotive OEMs, race teams have now taken the technology to the next level for the production of wind tunnel models and prototypes and race car parts in 3d printed plastic, metal and composites

AnyShape has a range of additive manufacturing technologies and high-performance materials suitable for all competition classes up to and including Formula 1. Our precision engineering department expertise in AM design, Topology optimization and weight reduction processes brings further benefits by opening up weight-saving opportunities using Nickel Alloys, Titanium Alloys and Scalmalloy® (Aerospace Aluminium Scandium alloy).

Races are won in research and development

When it comes to being successful on the track, it is the work that happens off it that really makes the difference, and with additive manufacturing, you can take your research and development into a higher gear with faster component interactions with more complex designs previously impossible with traditional manufacturing methods.

Not only can additive manufacturing help you create lighter and more complex parts, but it can also allow you to test and use new alloys and materials, helping you and your team set yourself apart from your competitors.

With AM your designers and engineers can have their prototype in their hands within days, not months, helping to cut down on lead times for new, more efficient components.

With Digital Inventory, you get your parts where you need them

When your vehicles change over the course of a season, it doesn’t make sense to keep a large inventory of parts that will become outdated before you ever use them.

With additive manufacturing, you can change how you manufacture and store parts, printing them when needed, cutting down on costly manufacturing and storage costs.Not only this, but you can continually update your products, improving on them throughout the season, helping to keep your team improving whilst others stall.

Our worldwide service means you can get the parts you need when you need them, it doesn’t matter if you are racing at iconic Monaco or the stunning Marina Bay Street Circuit in Singapore when you need the parts, you can have them printed and delivered on time.

FAQs

-

Do F1 teams use 3D printing?

Yes, F1 teams utilise 3D printing to produce wind tunnel models, prototypes, and car parts made from plastic, metal, and composites. By using 3D parts, they can achieve more efficient, faster, stronger, and lighter components than previously possible with traditional tooling methods, helping them to gain a competitive edge over their rivals.

-

What materials are commonly used in 3D-printed motorsport parts?

There is a huge range of materials used in additive manufacturing for the motorsport industry. Some of the most common include Nickel Alloys, Titanium Alloys, and Scalmalloy. These materials offer versatility, durability and weight reduction without compromising on strength and performance.

As additive manufacturing continues to grow within the motorsport sector, new materials are constantly being tested, helping to change the motorsport landscape faster than ever before.

-

Can 3D-printed parts be used in all levels of motorsport?

By combining additive manufacturing and high-performance materials, you can develop components for all types and levels of motorsport from endurance races to the pinnacle of Formula 1 racing. Additive manufacturing lowers the barrier to entry over traditional manufacturing methods and allows teams at all levels to improve their designs and their times.

-

How does 3D printing impact the research and development process in motorsport?

3D printing accelerates R&D by enabling rapid prototyping and testing of complex designs previously impossible with traditional methods. This leads to quicker development cycles, innovative use of new materials, and faster component interactions.

-

Are 3D-printed car parts safe?

Yes, 3D-printed car parts are safe. They undergo rigorous testing and optimization to ensure they meet the high standards required for performance and safety in motorsport. The use of advanced materials and precision engineering further enhances their reliability and effectiveness.