What is MultiJet 3D printing?

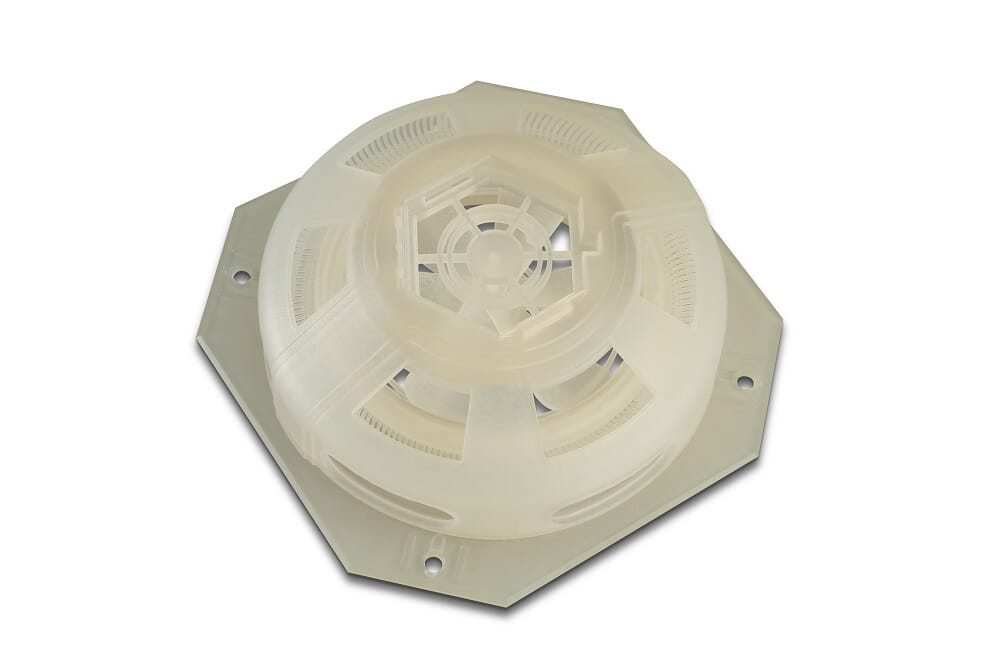

Our 3D Systems ProJet3600 MAX 3d printer produces highly detailed and accurate fit, form and functionality models in a wide range of VisiJet advanced materials

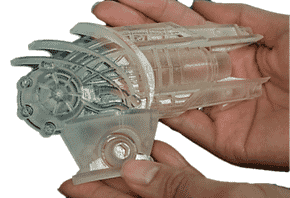

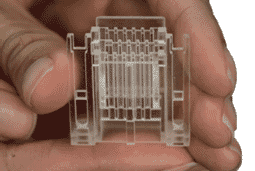

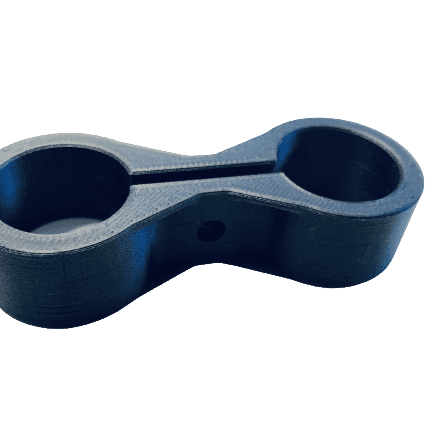

Micron precision MultiJet 3D printing technology enables product designers and design engineers to visualize their ideas and functionally test features such as thin wall sections, snap-fits, interference fits, clasps, threads, living hinges, fine channels and moving component assemblies.

Due to the fine print resolution and excellent surface finish, MultiJet parts can be used to test and verify injection mould tool designs and they can also be easily painted or metal coated.

Anyone involved in design for additive manufacturing will benefit greatly from these parts and the large range of 3D Printing Plastic Properties to choose from.

3D printed MultiJet parts can be produced as fully cleaned parts.

View our system specification below and download a materials specification sheet.