Key advantages of additive manufacturing

Additive Manufacturing Advantages

Additive Manufacturing provides numerous benefits compared to traditional manufacturing:

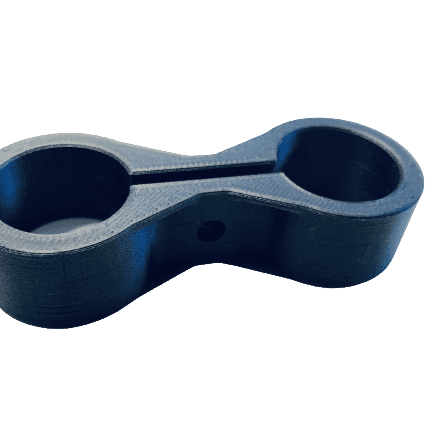

- Design Flexibility: Enables intricate and complex designs that are difficult with conventional methods, fostering innovation and customization.

- Reduced Waste: Builds objects layer by layer, minimizing material wastage and promoting sustainability.

- Faster Prototyping: Allows rapid iteration and testing of design concepts, speeding up product development and time to market.

- Cost-Effective for Low-Volume Production: Economically viable for small production runs, eliminating costly tooling and setup.

- On-Demand Manufacturing: Products can be made as needed, reducing inventory and enabling a just-in-time production model.

- Complex Assemblies: Creates fully assembled components, simplifying supply chains and reducing the need for assembly lines.

- Material Variety: Works with a wide range of materials, offering diverse applications across industries.

- Weight Reduction: Enables lightweighting for improved fuel efficiency and performance in aerospace and automotive sectors.

- Customization and Personalization: Allows products to be tailored to individual preferences, needs, and body shapes.

- Accessibility to Innovators: Lowered barriers to entry for inventors and small-scale manufacturers, fostering innovation and creativity.

Additive manufacturing has revolutionized production, promising transformative impacts on various industries and driving future innovations.