What Is Selective Laser Sintering?

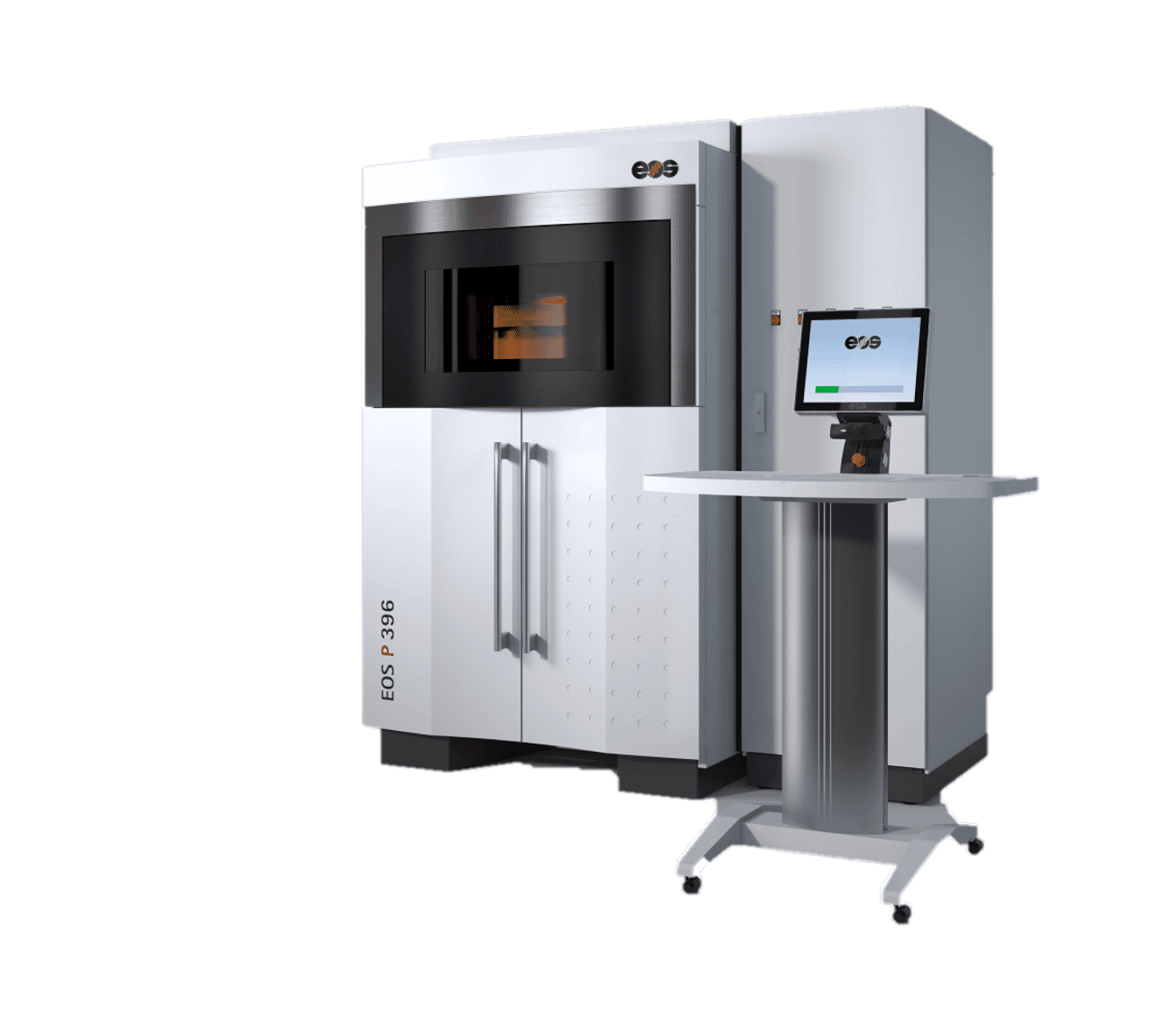

Selective Laser Sintering uses powder based additive manufacturing technologies incorporating a high-powered laser to fuse material particles together

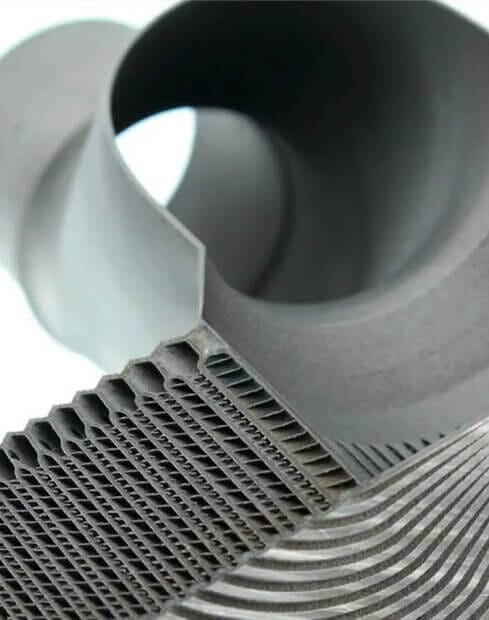

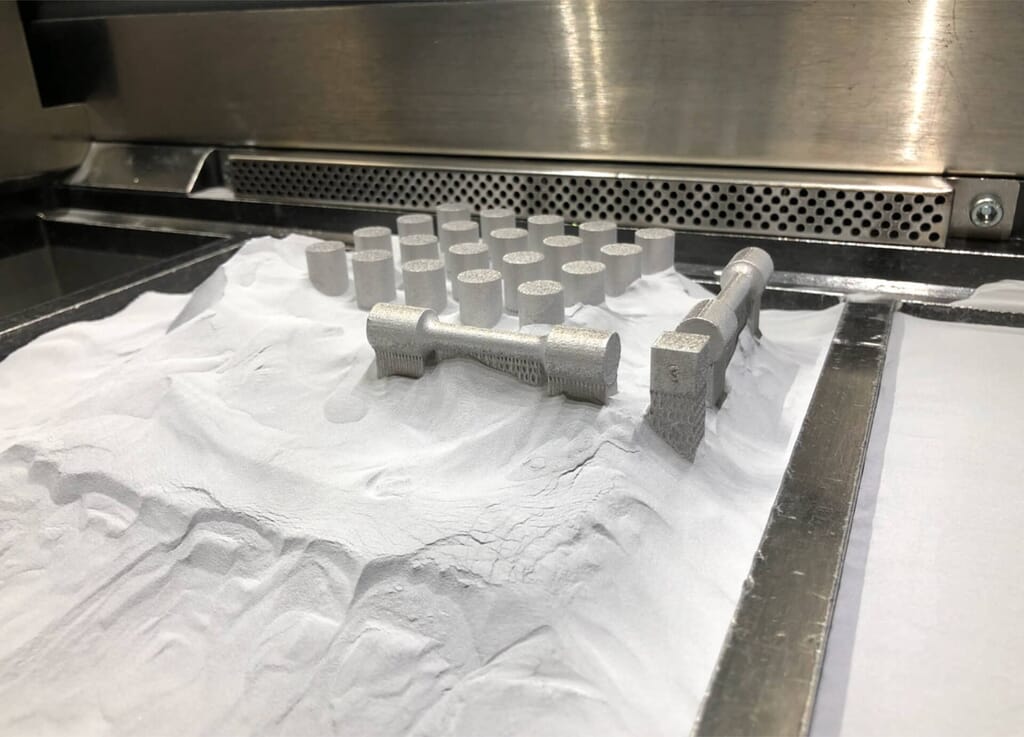

This proven and reliable fusion process takes place layer by layer, building the 3d printed part from the bottom up. Any un-sintered material can then be removed, filtered, and re-used as part of the material recycling process.

AnyShape can print parts in a variety of polyimide powders, including PrimePart ® PLUS PA2221, a refreshed optimised polyimide 12 powder with a high recyclability rate. Reducing the need for new powder and making parts using PrimePart® PLUS both economically and environmentally attractive.

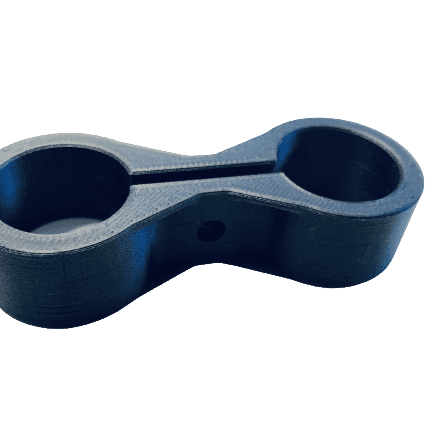

Selective laser sintering can be used for 3d printing engineering plastics for rapid prototyping, rapid tooling, jigs and fixtures and also 3d printing small plastic parts for end-use applications.

Parts can be surface finished, smoothed, painted, dyed and treated with special coatings.