Additive manufacturing is a process that offers total manufacturing flexibility and makes good economic sense too

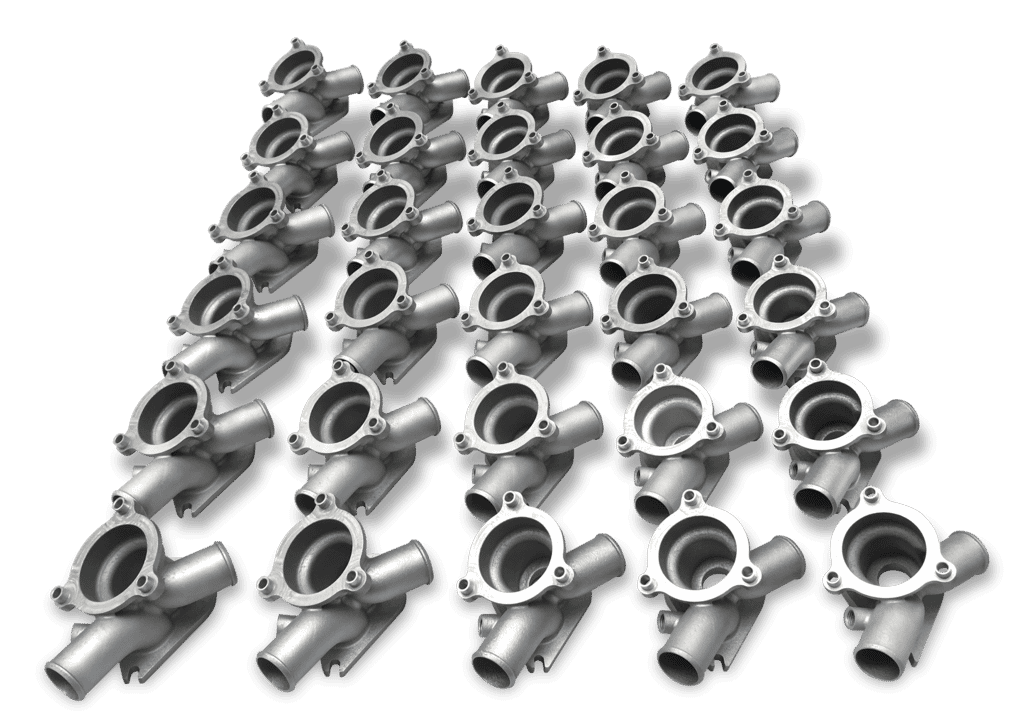

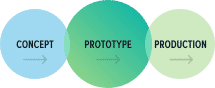

Take this example from one of our customers involved in the world of motorsport and 3d printing. For a number of years our client has needed the capability to design and additively manufacture engine cooling components for a number of competition vehicles. Once the final design was approved, metal prototypes were produced and performance tested on the track. The prototyping stage enabled the customer to identify potential weak areas in the design at an early stage and then re-engineer and optimise the design before going in to full scale production.

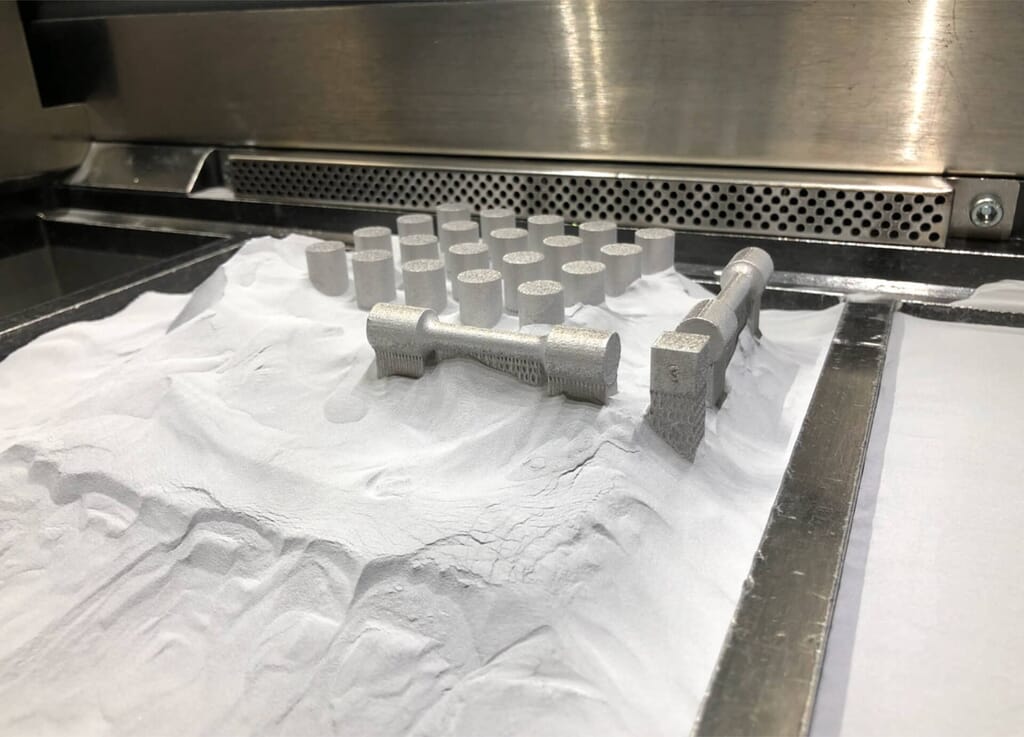

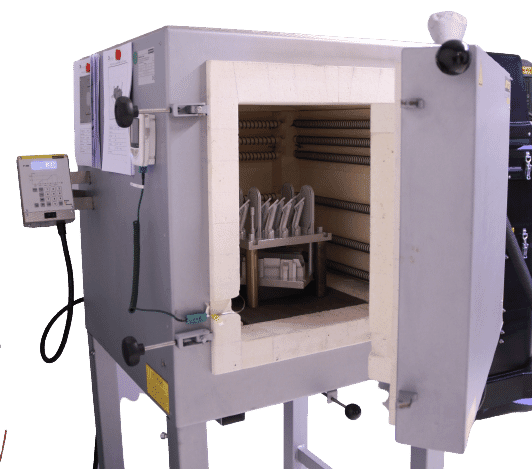

Utilising AnyShape’s digital 3d printing batch production services, parts are produced to order using Direct Metal Sintering in Aluminium.

As well as a producing 3d parts in various grades of steel, aluminium, titanium, nickel-alloy and copper, since 2018 AnyShape has been an approved and certified member of the Scalmalloy® distribution and manufacturing program of APWORKS GmbH (a subsidury of Airbus).

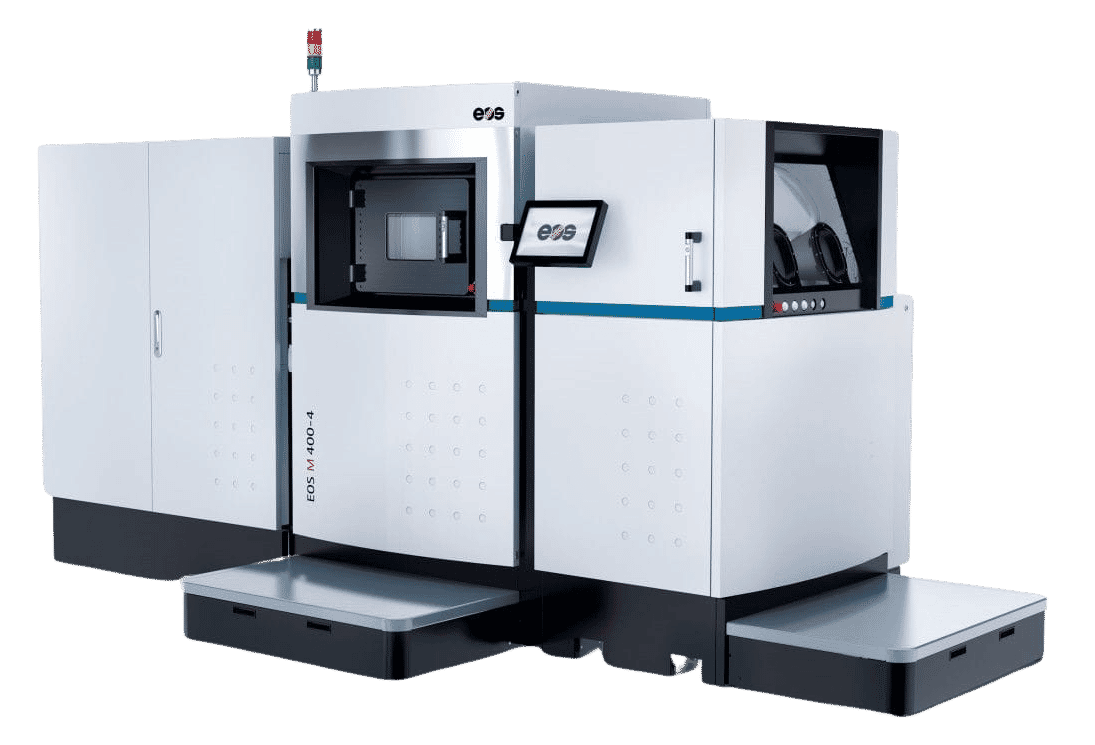

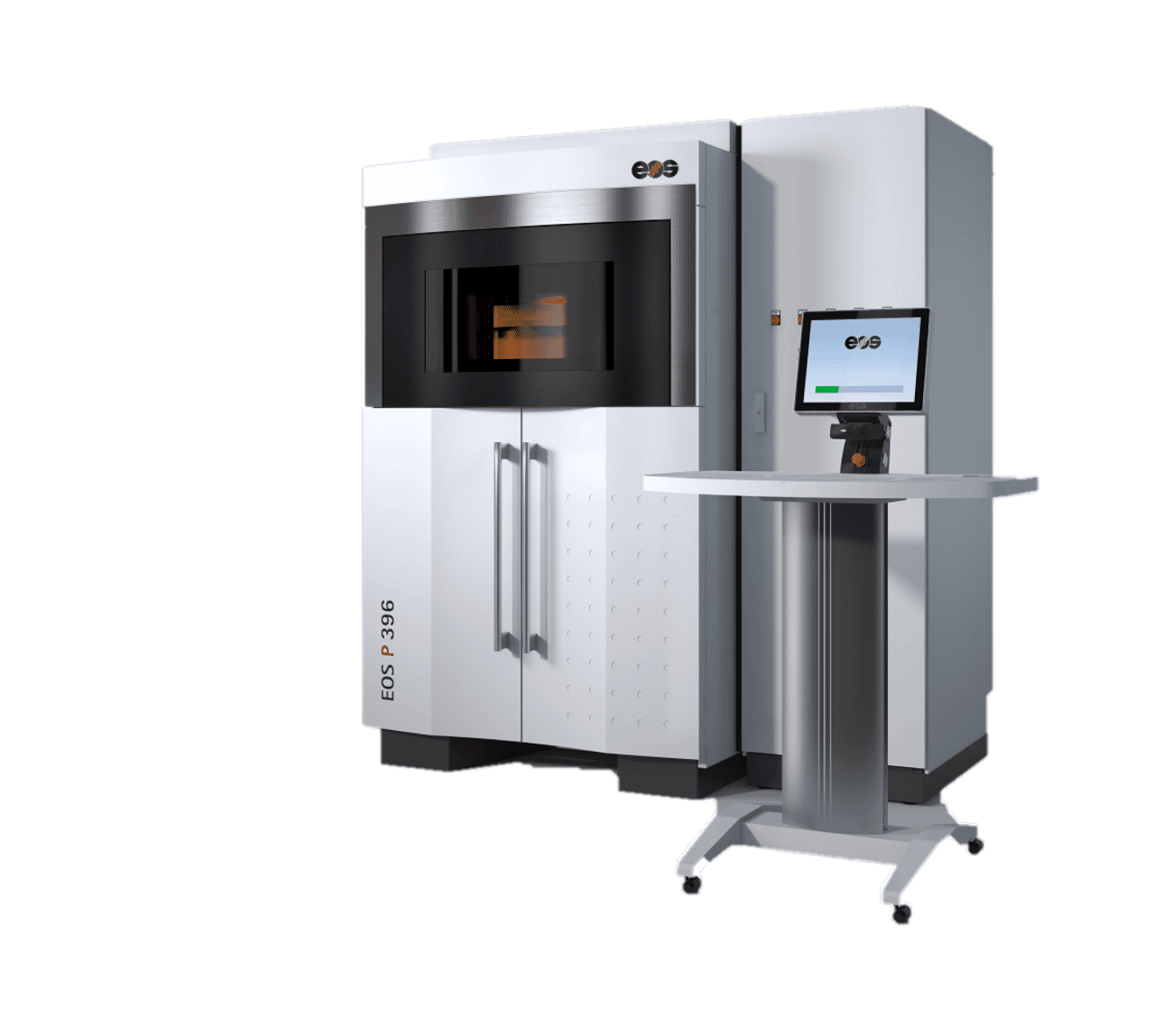

Scroll through our range of additive manufacturing systems below and download Materials Technical Data Sheets for Metals, Plastics and Composites.