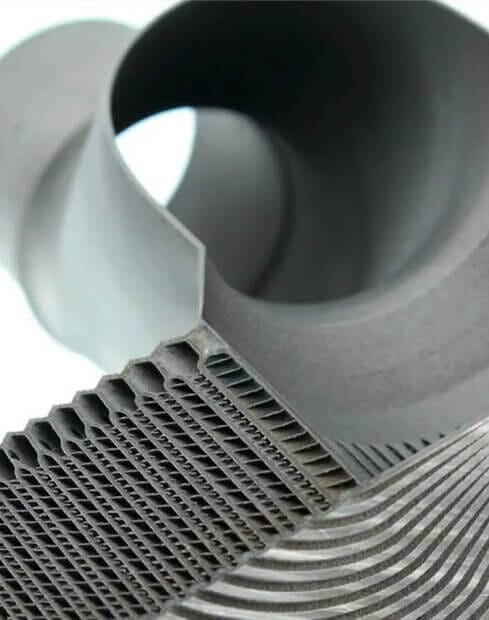

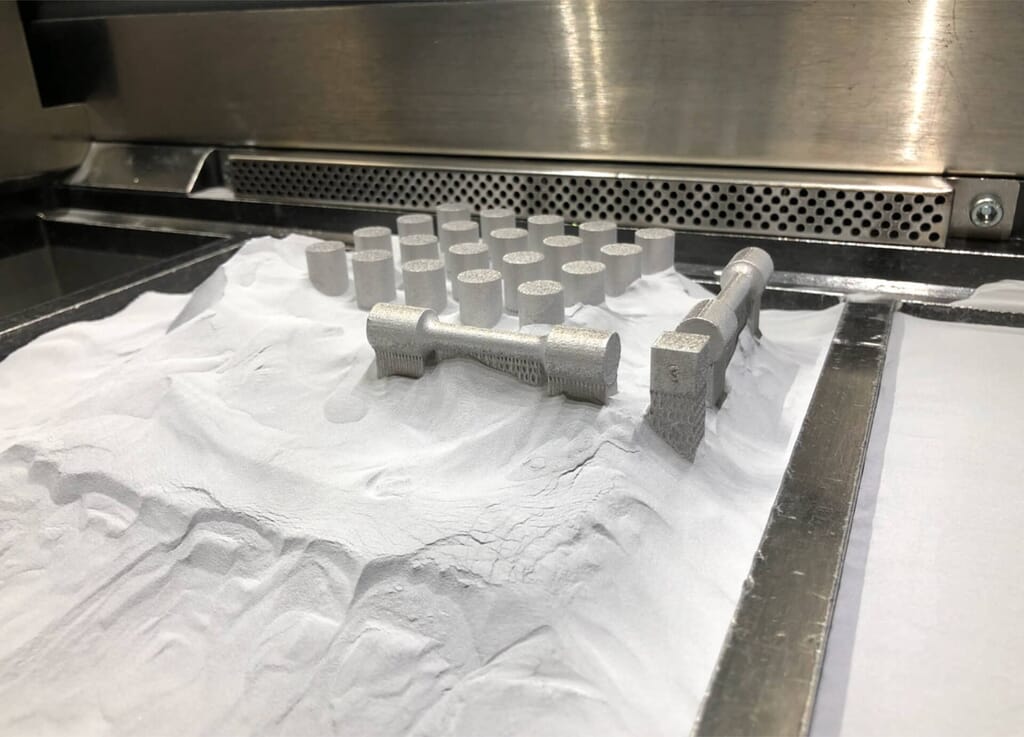

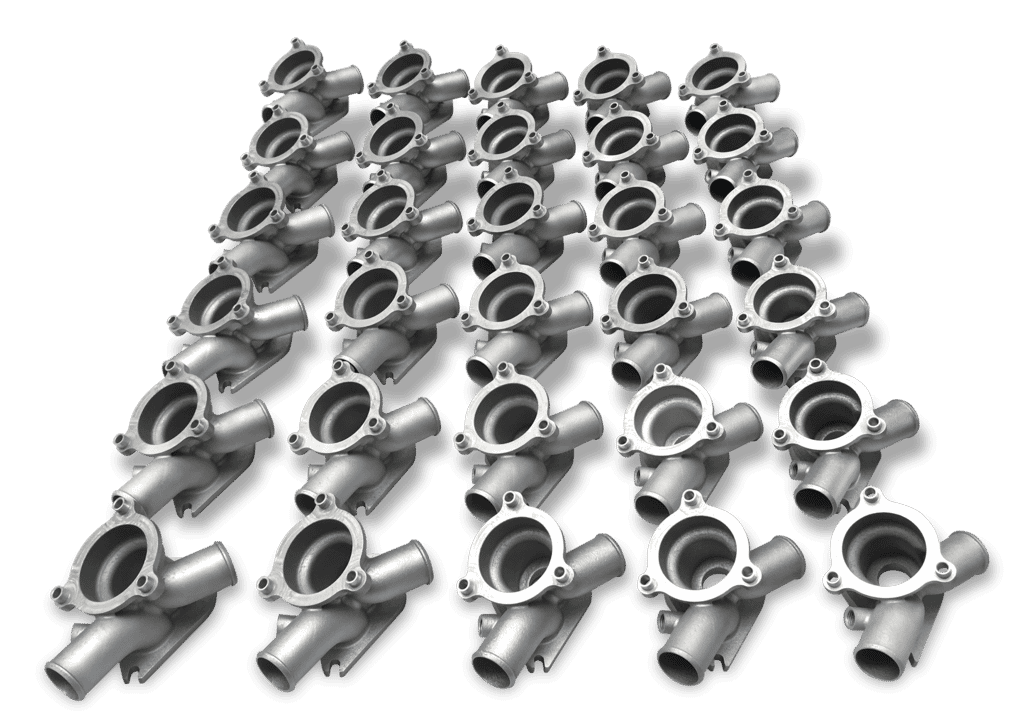

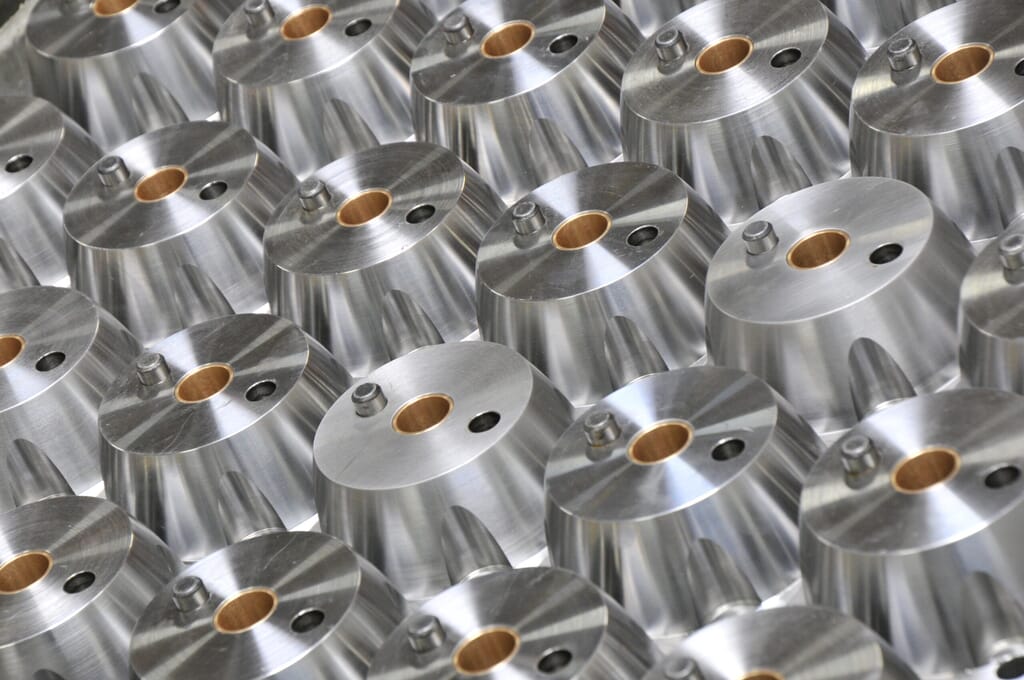

One of the major benefits of partnering with AnyShape is our unique breadth of in-house capabilities

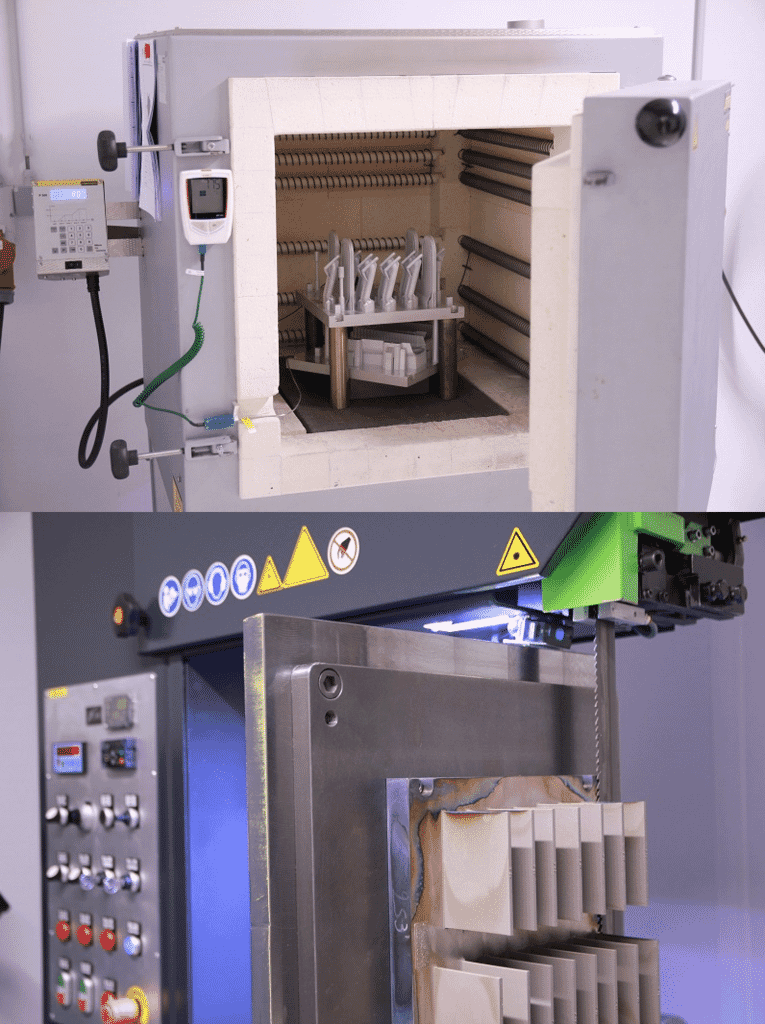

In many cases additively manufactured parts need to be post-processed and finished before they can be put in to service and used. When it comes to part post-processing and special treatments, AnyShape’s engineering department can meet the need. Not only do we offer state of the art 3d design and printing services, but our inhouse post-production services ensure complete control of the production steps whilst reducing global lead times. Our extensive additive manufacturing services include machining, stress relief and thermal treatment, media blast surface finishing, polishing and tribofinishing, painting and hot impregnation for colouring

Additionally, should your parts require special coatings to meet aerospace, space or medical approvals, qualification or regulatory needs, then these can be arranged also to simplify your supply chain and reduce associated supply chain costs