AnyShape excels in the area of R&D by developing custom parameter settings and custom materials for metal additive manufacturing

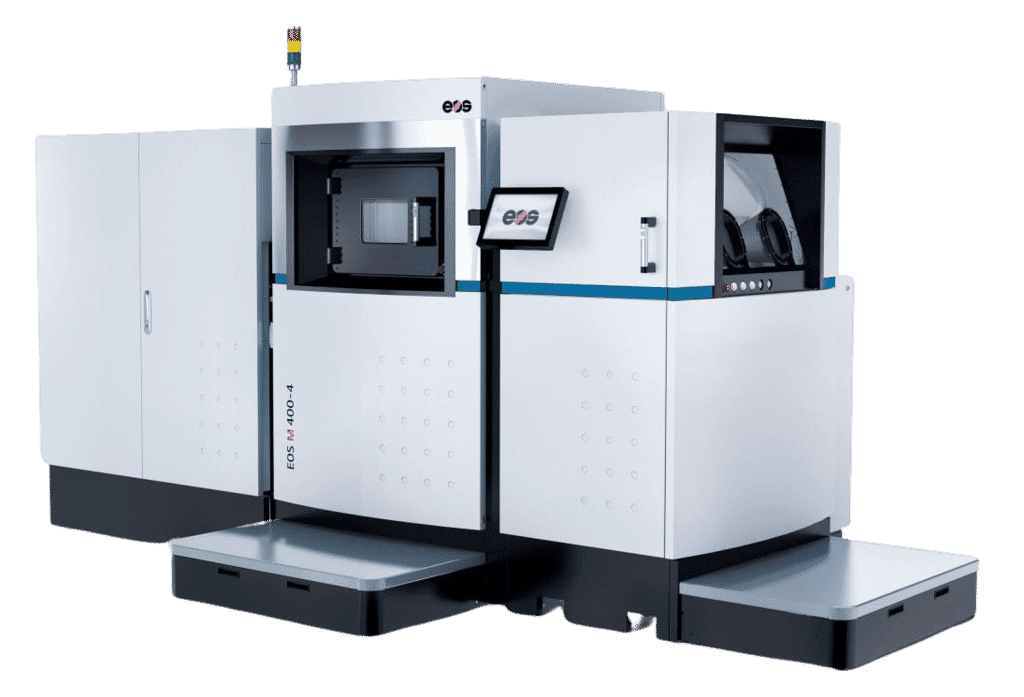

Direct Metal Laser Sintering

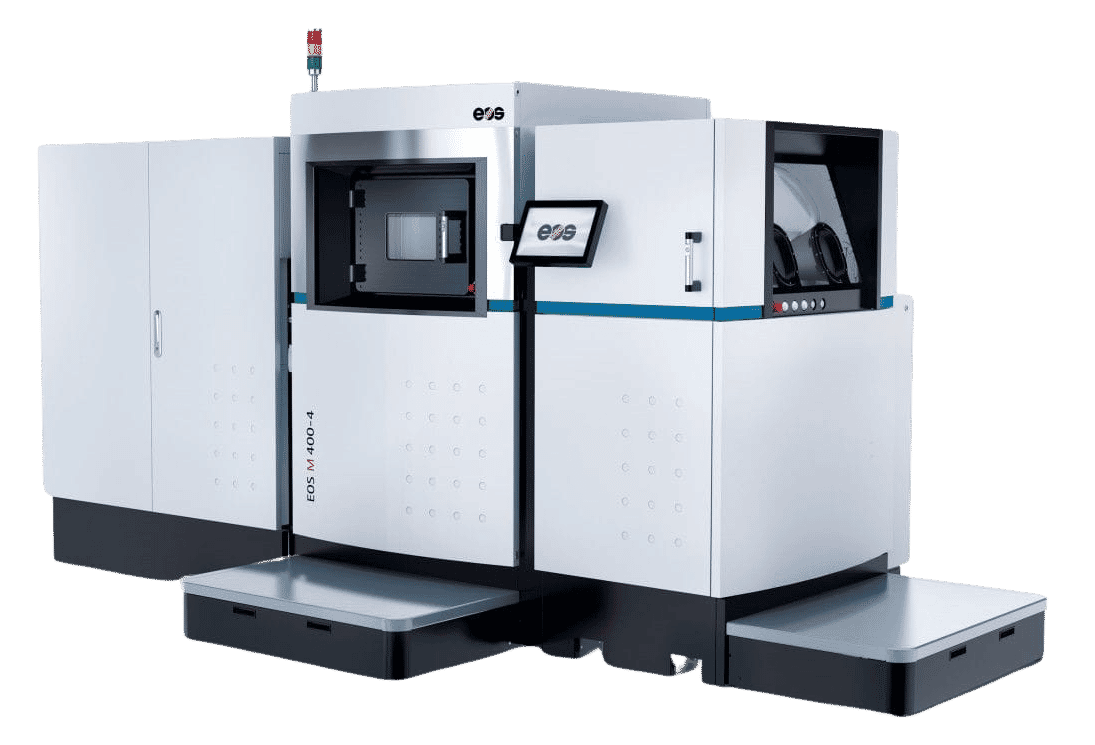

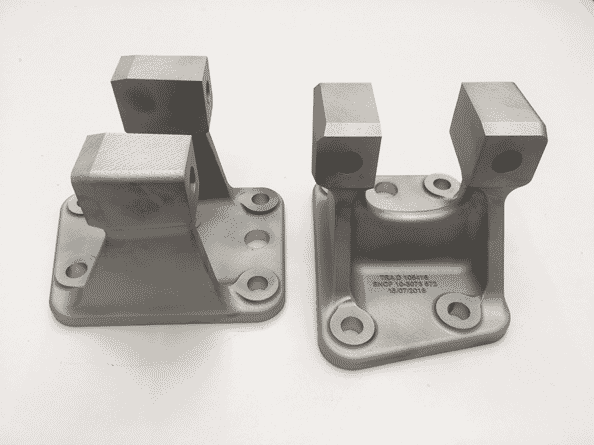

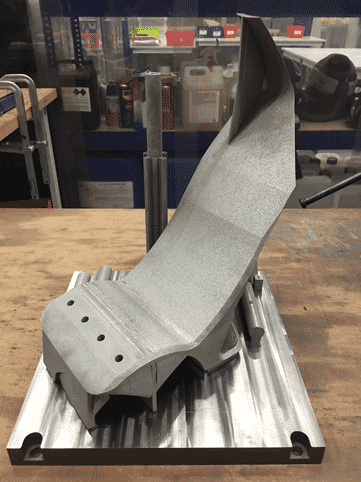

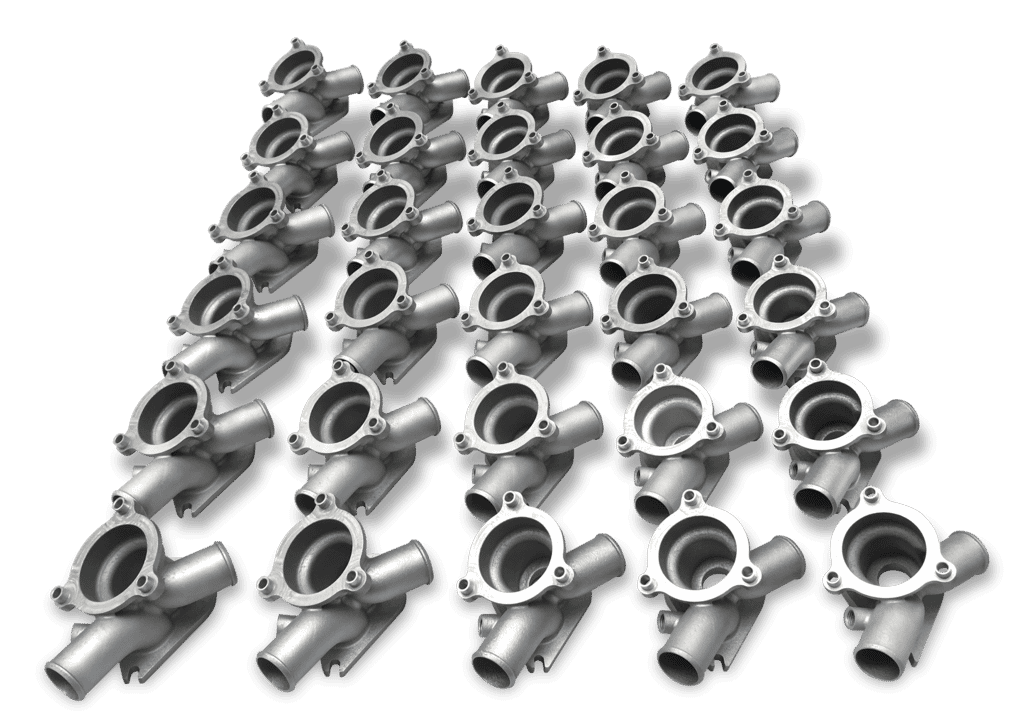

As one of the most advanced and reliable technologies in metal additive manufacturing, direct metal laser sintering (DMLS) has become synonymous within metal 3D printing and manufacturing. The pioneering technology is used throughout an abundance of sectors, from crafting automotive and motorsport parts to printing high spec aerospace components.

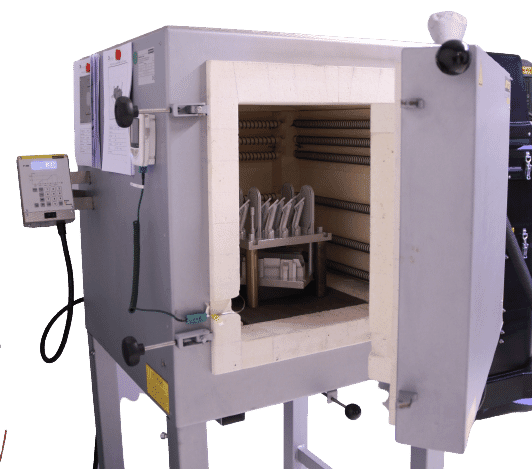

DMLS uses high-powered lasers and fine metal powders produce the very highest quality metal parts available. These material powders include steels, copper, alloys, nickel-alloys and super-alloys. At AnyShape we have spent many years refining this process further, developing the technology and its capabilities to continually improve overall part quality, performance and surface finish.

As one of the UK’s leading 3d printing suppliers we offer a wide range of metals and metal powders and free additive manufacturing consulting services. With our unrivalled experience we guarantee to add value to each and every project.

If you’d like to discuss a project, or learn more about our metal 3d printing services please get in touch with the team today.