Flying higher with additive manufacturing

In the ever-changing world of aviation, precision and safety are paramount. At AnyShape, we don’t just meet industry standards; we set new benchmarks. Our flight-approved additive manufacturing solutions for aviation parts deliver unmatched quality and performance, enabling manufacturers to push the limits of what’s possible. Whether it’s for commercial airliners or cutting-edge aviation projects, our technologies elevate aircraft innovation to new heights.

Accelerating innovation in aviation

The aviation industry demands constant innovation to stay competitive. At AnyShape, we’re dedicated to keeping pace with these demands by offering advanced additive manufacturing solutions that enable faster design cycles, better customization, and significant cost efficiencies. Our fully digital supply chain ensures rapid delivery of high-quality components, from initial prototypes to flight-ready parts, so you can bring your aircraft innovations to market faster and with greater confidence.

Optimizing aircraft performance with advanced manufacturing

When every gram counts, additive manufacturing for aviation delivers unparalleled advantages. Our expertise in creating lightweight, high-strength components allows for improved fuel efficiency, weight reduction, and part consolidation, making aircraft lighter and more efficient. By integrating advanced 3D printing into your manufacturing process, you not only optimize performance but also reduce maintenance needs, resulting in lower operational costs and enhanced reliability. AnyShape’s solutions are engineered to help your aircraft perform at its best.

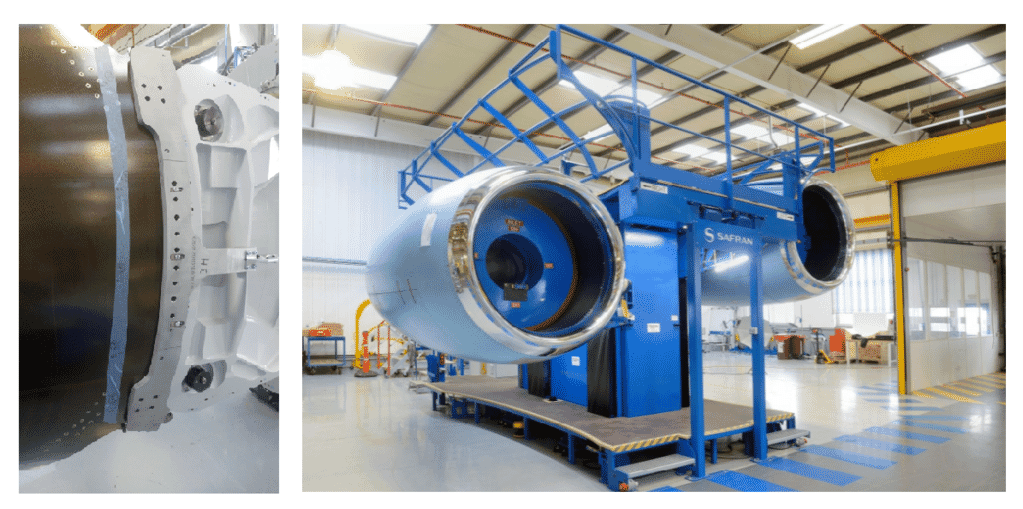

Metal 3D printing: from concept to cockpit

Metal 3D printing is transforming how aviation components are designed, tested, and manufactured. With the ability to produce complex geometries and intricate internal structures, our metal additive manufacturing technologies offer unprecedented flexibility. Engineers can push boundaries and design parts that weren’t feasible with traditional methods, achieving new levels of efficiency and performance. Our on-demand capabilities also minimize logistical challenges and inventory costs, creating a leaner and more adaptable aviation supply chain.

Exceeding expectations in aviation manufacturing excellence

From initial design consultations to post-production quality assurance, AnyShape offers a comprehensive approach to additive manufacturing for aviation. Our state-of-the-art facilities and industry expertise ensure that every component we produce not only meets but exceeds the stringent safety and performance standards required for flight. By partnering with AnyShape, you’re choosing a smarter approach to aviation manufacturing; one that keeps you at the forefront of innovation, whilst setting new standards for efficiency and safety.

Trusted by engineers worldwide

FAQs

-

How does AnyShape ensure the quality and compliance of aviation parts?

AnyShape adheres to strict quality and compliance standards, employing rigorous testing and validation processes throughout our additive manufacturing services. We ensure that every aviation part meets the highest industry standards for safety and performance, providing peace of mind that each component is flight-ready.

-

What advantages does additive manufacturing offer for aviation parts?

Additive manufacturing for aviation offers numerous advantages, including improved fuel efficiency through weight reduction, rapid prototyping, and the ability to produce complex geometries that are not possible with traditional manufacturing methods. This leads to the production of more efficient, high-performance aviation parts.

-

Can AnyShape handle large-scale production needs?

Yes, AnyShape is equipped to handle large-scale production requirements, offering scalable solutions that cater to the unique needs of the aviation and aerospace industries. Our advanced additive manufacturing facilities are designed to accommodate high-volume production, ensuring that we can deliver large quantities of parts without compromising on quality or performance.

-

How does AnyShape contribute to sustainability in aviation?

AnyShape’s additive manufacturing processes significantly reduce waste by utilizing materials more efficiently. This, combined with the production of much lighter parts, leads to lower fuel consumption and contributes to a more sustainable future in aviation.