3D printing common problems – and how to avoid them

In the right hands, almost every business stands to benefit from additive manufacturing. But as with any technology, it’s worth taking a little time to grasp the dos and don’ts. Here, the AnyShape team runs through some 3D printing common problems that could stop you getting the most from AM.

3D Printing Common Problems #1 – Using the wrong material

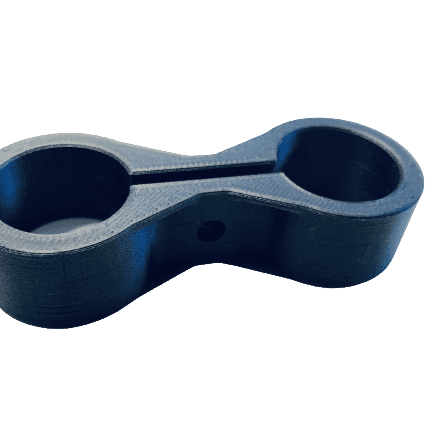

The wide and rapidly growing range of 3D print materials is a key benefit of AM. With a choice of metals, nylons, thermoplastics, resins, ceramics and more, it’s possible to specify a material with the exact qualities needed for the application, whether that’s strength, stiffness, flexibility, resistance to heat and chemicals, or a thousand other variables.

The flipside is that using the wrong material can have a disastrous impact on the final printed component, resulting in anything from poor resolution to geometric inaccuracies. At Anyshape, we not only offer a comprehensive range of 3D print materials, but can expertly guide you to the right one, whether it’s for our 3D metal printing service or plastic rapid prototyping.

3D Printing Common Problems #2 – Choosing the wrong 3D print technology

Materials are not the only consideration when it comes to successful 3D printing. Just as critical is matching the optimal material with the correct print technology, and understanding this delicate partnership is just one area of AnyShape’s expertise.

As a general rule of thumb, Fused Deposition Modeling (FDM) is most commonly used for 3D printing using materials like ABS, PLA (and the various blends thereof). Stereolithography (SLA) is commonly used with resins, while Selective Laser Sintering (SLS) is a good choice when working with nylons and composites.

But with the list of materials growing all the time – and AnyShape constantly adding to our selection of 3D printable metals to complement our 3D metal printing service – it’s always best to ask our experts which technology they’d recommend for the project at hand.

3D Printing Common Problems #2 – Choosing the wrong 3D print technology

Materials are not the only consideration when it comes to successful 3D printing. Just as critical is matching the optimal material with the correct print technology, and understanding this delicate partnership is just one area of AnyShape’s expertise.

As a general rule of thumb, Fused Deposition Modeling (FDM) is most commonly used for 3D printing using materials like ABS, PLA (and the various blends thereof). Stereolithography (SLA) is commonly used with resins, while Selective Laser Sintering (SLS) is a good choice when working with nylons and composites.

But with the list of materials growing all the time – and AnyShape constantly adding to our selection of 3D printable metals to complement our 3D metal printing service – it’s always best to ask our experts which technology they’d recommend for the project at hand.

3D Printing Common Problems #4 – Incorrectly set up 3D printer

Once you have some experience under your belt, 3D printers are intuitive to work with. But for an uninitiated operator who is working with a new model for the first time, setting up incorrectly – or neglecting vital factors like the build face orientation – will practically guarantee a poor result.

At AnyShape, we not only have state-of-the-art 3D printing technology at our fingertips, but also the expert team on hand to ensure that every last piece of hardware functions as it should.

What’s the best way to avoid 3D printing common problems?

Talk to AnyShape. We’re proud to be one of Europe’s most trusted AM experts, offering a full portfolio of in-house services from 3D metal printing service to plastic rapid prototyping, and guiding you with passion and honesty to the best technologies and materials for your individual needs.

Get in touch with AnyShape