Examples of Rapid Prototyping in 3D Printing

Businesses across the planet rely on rapid prototyping to fine-tune their product before it rolls out. Read on to discover how 3D printing technology has changed the playing field – and why a professional rapid prototyping service is invaluable.

Rapid prototyping has long been used by the world’s designers to create, assess and launch new products at pace. But the rise of 3D printing has massively accelerated the time-to-market, while boosting efficiency, economic benefits and even design innovation.

With AnyShape’s rapid prototyping service firmly established as one of our core offerings, let’s take a closer look at what this technology involves.

What is rapid prototyping and where does 3D printing come in?

A prototype is an work-in-progress physical representation of a component or assembly. It’s created to show a designer how their final product might look, feel and function – and let them make the necessary adjustments.

Typically, a designer will create and assess various different prototypes as the component moves through the production process. In decades past, this was an arduous job, with each minutely adjusted prototype outsourced to a third-party manufacturer, resulting in expense and delay as tooling and logistics were adapted to the designer’s changes.

Fortunately, 3D printing has transformed the possibilities of rapid prototyping, slashing time-to-market, letting designers easily test and improve their work and allowing an agility that wasn’t possible with traditional manufacturing methods like milling and casting. With AnyShape’s rapid prototyping service, a design file on a laptop can become a physical object faster than ever before.

What are some examples of rapid prototyping?

Given that almost every sector uses rapid prototyping to assess countless different components, all performing different roles, it follows that a range of 3D print technologies are needed to meet these almost-infinite criteria.

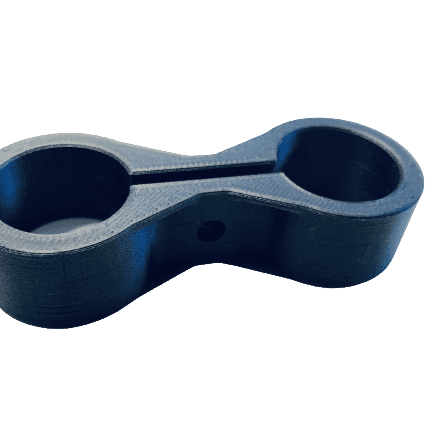

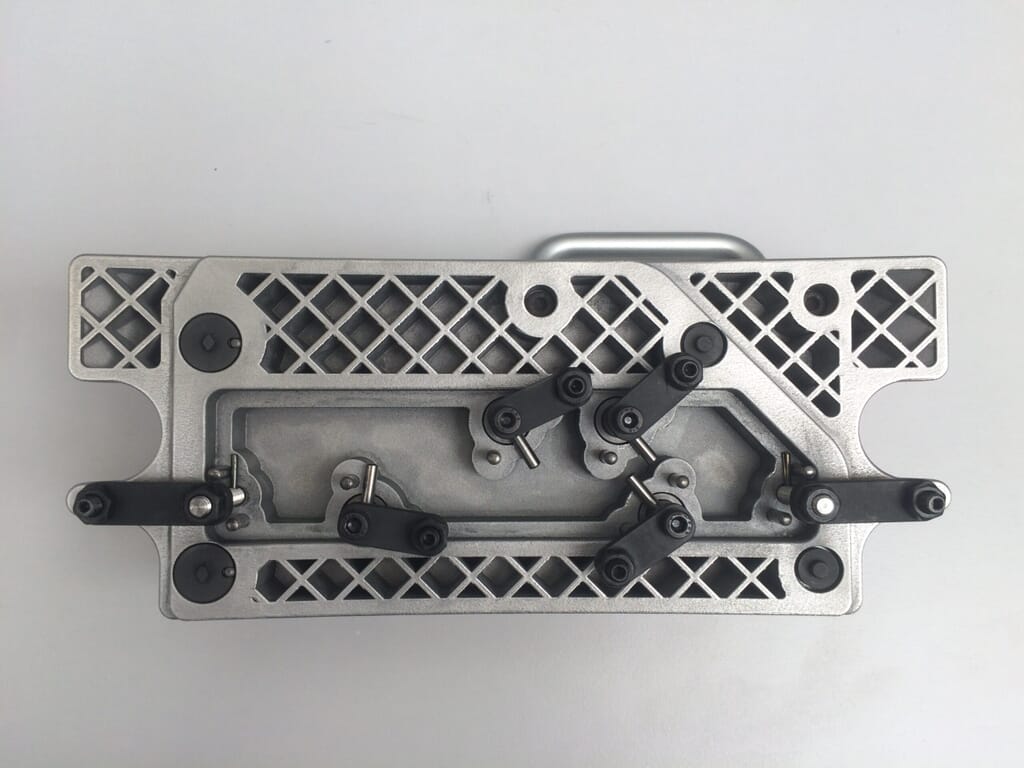

With state-of-the-art AM technologies and post-processing equipment at our fingertips, AnyShape’s rapid prototyping service runs the gamut. We’re just as experienced working with Stereolithography/SLA (often used for plastic parts) as Fused Deposition Modeling/FDM (ideal for ABS or PLA thermoplastics). Powder Bed Fusion (PBF) can be a good option for metal components, while Selective Laser Sintering (SLS) is often chosen for parts with complex geometries.

But there are few hard and fast rules. When you ask AnyShape about our renowned rapid prototyping service, we’ll start by considering the individual part and application before guiding you towards the most appropriate 3D print technology. We’ll also be happy to talk you through our growing selection of rapid prototyping materials.

Which industries use rapid prototyping – and what sort of components do they make?

AnyShape has offered our rapid prototyping service to businesses across every sector – from aerospace to defence – and helped develop everything from a standard 3D product mockup to a highly specialised rocket thruster bracket. In each case, we’ve helped our clients to dramatically cut costs and time-to-market, while guiding them to an optimised product.

Where can I find a professional rapid prototyping service?

Right here at AnyShape. We’re one of Europe’s most trusted experts in AM, offering a complete portfolio of in-house services to take your project from drawing board to final product, and guiding you with passion and honesty through the optimum technologies and materials for your business needs.

Get in touch with AnyShape