What is the difference between SLS and DMLS?

Selective Laser Sintering and Direct Metal Laser Sintering are two of the core processes used in additive manufacturing. But what does each one involve – and how can it benefit your business?

For businesses taking their early steps into additive manufacturing, the sheer breadth of 3D print processes can be bewildering. At AnyShape, we’re often asked for clarification on two processes – Selective Laser Sintering and Direct Metal Laser Sintering – that sound similar but in fact involve quite different technology and materials. So, what is the difference between SLS and DMLS?

What is Selective Laser Sintering (SLS)?

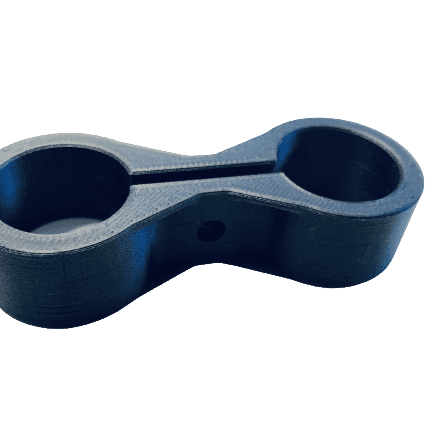

SLS is highly prized for its flexibility. This technology can be used with a wide range of materials, including glass, ceramics, nylons and AnyShape’s comprehensive range of polyimide powders like PrimePart ® PLUS PA2221.

As established SLS specialists, AnyShape has partnered with the gamut of business sectors – from engineering to healthcare – and offered our expertise for applications ranging from rapid prototyping and tooling, to jigs and fixtures and small-sized plastic parts for end-use applications.

What is Direct Metal Laser Sintering (DMLS)?

When it comes to metal additive manufacturing, Direct Metal Laser Sintering is one of our most trusted and popular technologies. DMLS uses a powerful optic laser to melt ultra-thin layers of metal powder and create 3D printed parts layer-by-layer, direct from CAD drawings on a designer’s laptop.

In the right hands, DMLS also offers a superior print quality to most AM technologies, with the uniform distribution of metal powders allowing the reliable build of feature-rich components and intricate or complex structures like honeycomb. Inspect a part built using Direct Metal Laser Sintering and you’ll also note a superior finish to tooled or wrought materials. At AnyShape, we’re experts at processing DMLS parts, too, working with your specifications to post-machine, paint and resurface components as required.

What is DMLS used for?

AnyShape’s state-of-the-art DMLS printer technology is complemented by the vast selection of available metal powders. These span from stainless steels, tool steels, coppers and aluminiums, to nickel-based alloys, titanium alloys and patented high performance super-alloys like ™Scalmalloy.

Because of these almost-limitless material options, AnyShape’s Direct Metal Laser Sintering service is chosen by a wide range of industries – aerospace, automotive, defence, energy, oil, motorsport and medical, to name just a few. Due to DMLS’s fast turnaround times, it’s often used for rapid prototyping – and with no need for time-intensive tooling, many of our clients rely on this technology for low-volume runs and unique production parts.

Where can I find out more about SLS and DMLS?

Talk to the AnyShape team. We’re one of Europe’s most trusted experts in additive manufacturing, offering a complete portfolio of in-house services to take your project from drawing board to final product, and guiding you with passion and honesty through the optimum technologies and materials for your business needs.

Get in touch with AnyShape