What is Laser Sintering used for?

It’s a core additive manufacturing technology – but what is laser sintering used for? Discover the applications and related industries of both Direct Metal Laser Sintering (DMLS) and Selective Laser Sintering (SLS) here.

What is Direct Metal Laser Sintering?

As one of the most common technologies in metal additive manufacturing, AnyShape is regularly called upon for our Direct Metal Laser Sintering service. The basic principle is always the same, with DMLS involving the melting of ultra-thin metal powder layers with a high-powered optic laser, and the layer-by-layer printing of 3D objects. But the flagship benefit of DMLS – namely, its ultra-accurate printing of highly intricate and complex structures – means this technology is used for countless different applications across myriad sectors.

What is Direct Metal Laser Sintering used for?

Amongst our DMLS clients, AnyShape counts designers and engineers from sectors including aerospace, automotive, defence, energy, oil, medical and motorsport. Because the process is so efficient – with no tooling required – it’s often chosen for rapid prototyping. But given that DMLS also ensures a higher-quality finish than tooled or wrought material, it’s regularly relied upon for small-scale manufacturing runs and one-off production parts.

You’ll find DMLS-produced components across global industry, from medical implants to aerospace parts that need to function in high-temperature environments. Any time that a component is rich in features or involves intricate/complex structures like honeycomb, DMLS is a powerful choice.

The far-reaching applications of DMLS are partly down to the huge choice of metal powders available for this technology. Most commonly used are alloy, stainless and tool steels, alongside aluminium, titanium, bronze and cobalt-chrome, each with their own unique properties and advantages. But at AnyShape, we have all the next-generation materials at our fingertips, too, including patented high performance super-alloys like ™Scalmalloy.

What is Selective Laser Sintering (SLS) used for?

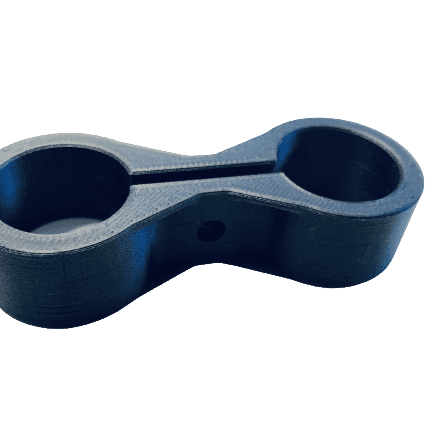

Of course, DMLS is not the only type of laser sintering. At AnyShape, we also offer Selective Laser Sintering (SLS), which employs a wide variety of materials including glass, ceramics, nylons and polyimide powders like PrimePart ® PLUS PA2221 (as opposed to DMLS, which uses metal alone). SLS is chosen for very different purposes: you’ll often see this technology used for rapid prototyping and tooling, or jigs/fixtures and small plastic parts for end-use applications.

Why choose AnyShape’s laser sintering service?

At AnyShape, we’re experts in every stage of the laser sintering process, giving guidance in optimising your design, directing you to the most suitable 3D printers and materials for your application, and even offering a suite of post-machining, painting and resurfacing services as required.

Other AM firms offer laser sintering, but only the AnyShape team goes further, refining the process for unbeatable part quality, performance and surface finish, while developing custom parameter settings and unique materials.

Our metal additive manufacturing solution is just one strand of AnyShape’s offering as Europe’s most trusted experts in additive manufacturing. From drawing board to final product, trust us to guide you with honesty and authority to the optimum AM technologies for your needs.

Get in touch with AnyShape