Accelerating production with advanced plastic 3D printing technologies

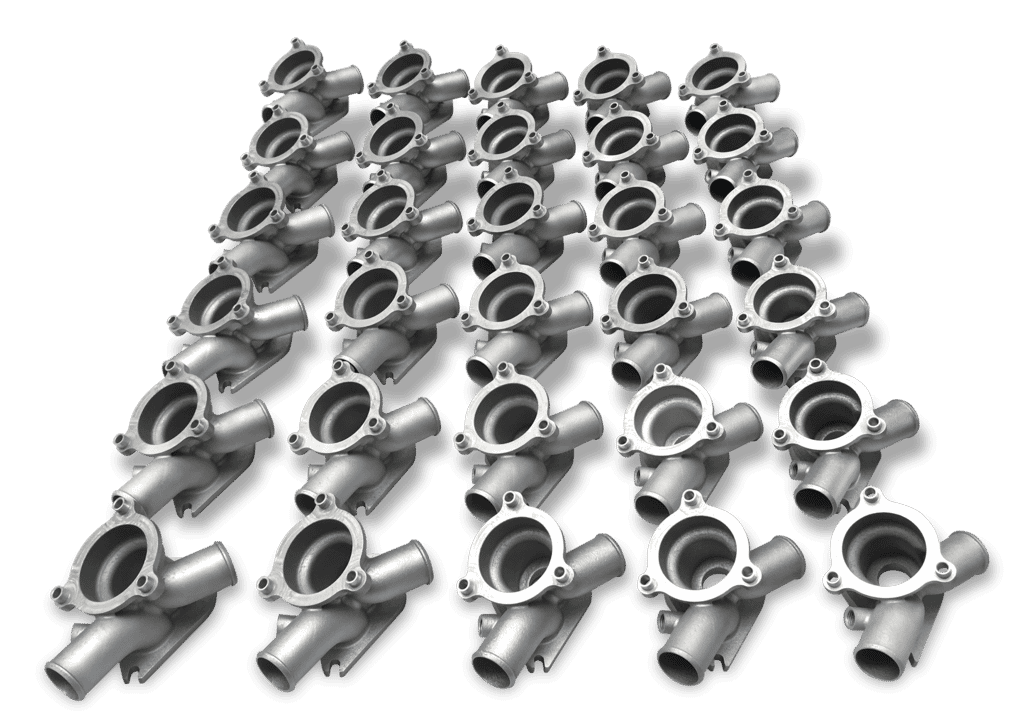

We offer a diverse array of additive manufacturing technologies and materials under one roof. Our advanced 3D printing manufacturing capabilities allow us to produce complex, lightweight, and high-performance plastic parts that cater to a wide range of industries. Whether you require rapid prototyping, durable end-use parts, or custom components designed for specific applications, we deliver high-quality results every time.

Our state-of-the-art plastic additive manufacturing services include:

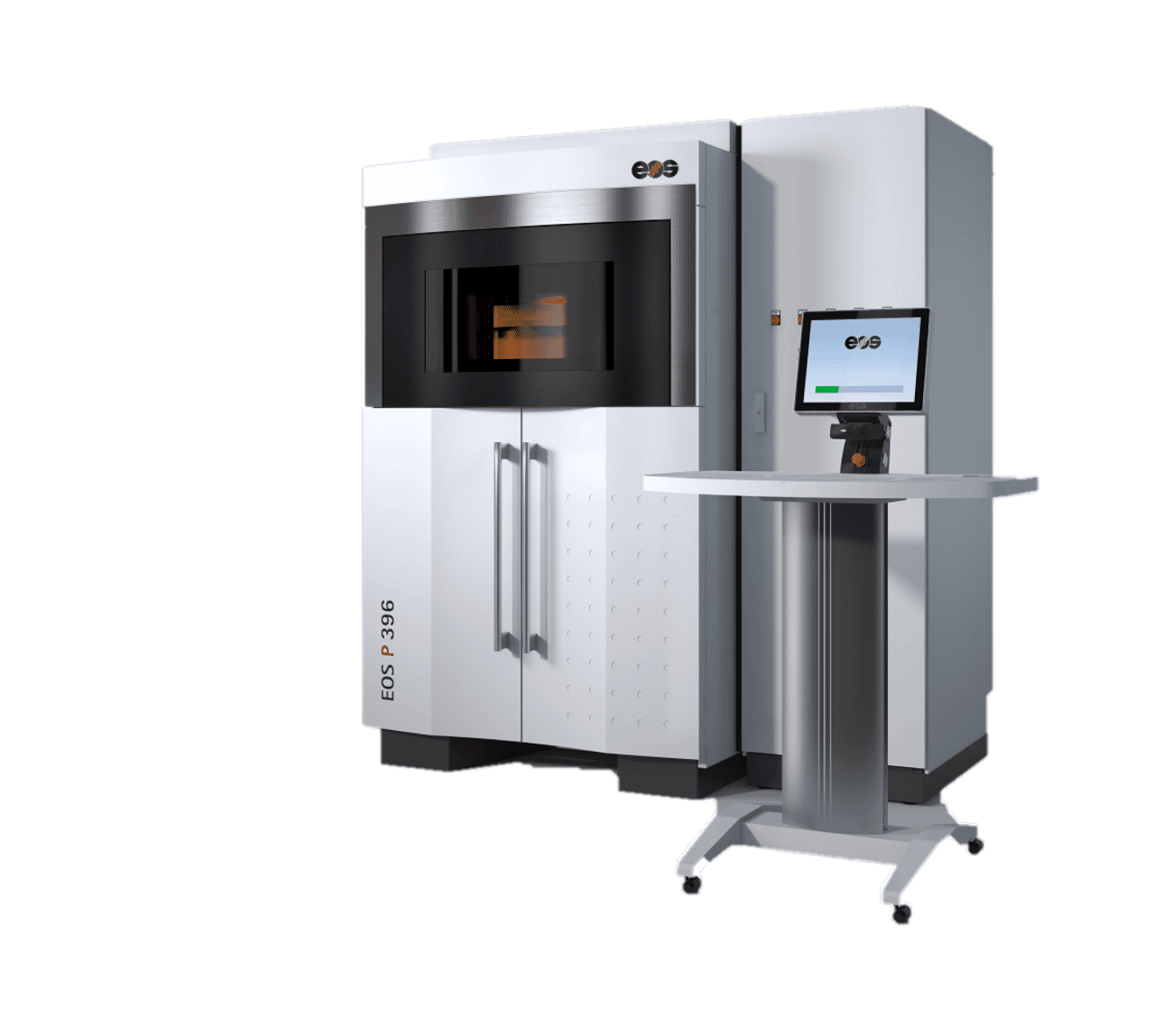

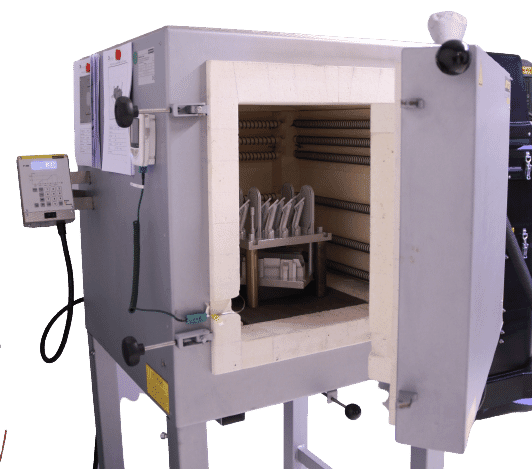

- Selective Laser Sintering (SLS): This technique uses a high-powered laser to fuse polymer powder into solid 3D structures, helping to create parts with complex geometries and durable mechanical properties that can withstand demanding environmental conditions.

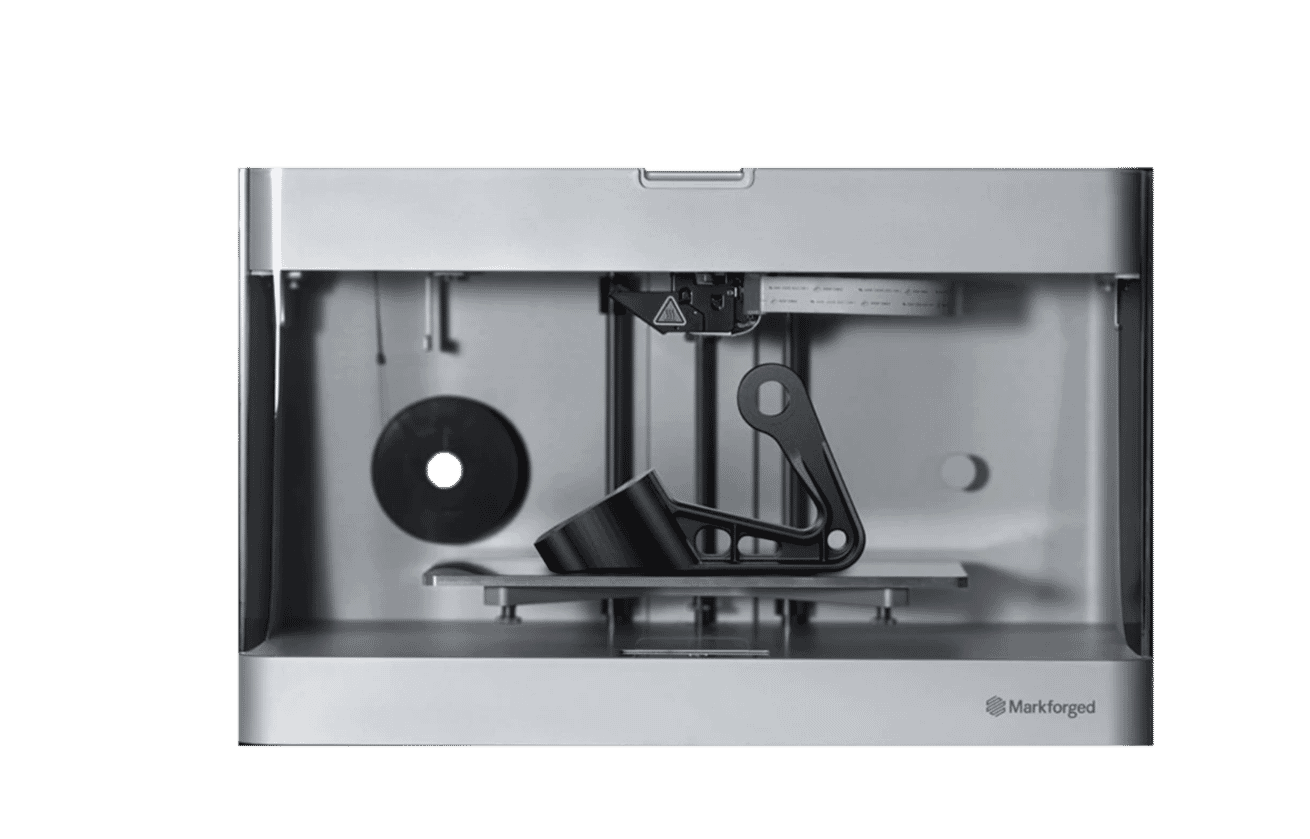

- Fused Deposition Modeling (FDM): FSM is a versatile, cost-effective 3D printing technology that extrudes thermoplastic filaments layer by layer to form solid parts. This method is perfect for producing large, sturdy parts using various thermoplastic materials such as ABS, PLA, and PETG.

- Continuous Fiber Fabrication (CFF): CFF integrates continuous fibers, like carbon or glass, into a polymer matrix, resulting in parts that are exceptionally strong and lightweight. This technology is suitable for the production of high-strength parts and is often used as an alternative to traditional aluminium components.

Applications across multiple sectors

- Automotive & Motorsport: Plastic additive manufacturing enables the production of lightweight yet strong components that help to improve vehicle efficiency and performance.

- Aerospace: Our advanced 3D printing solutions allow us to create complex, durable plastic parts that meet stringent aerospace industry standards.

- Healthcare: We produce biocompatible plastic parts and customized medical devices that meet stringent healthcare regulations and performance demands.

- Industrial & Consumer Goods: From functional prototypes to end-use components, our plastic 3D printing capabilities support a wide range of industrial and consumer applications.

Key benefits of AnyShape’s plastic additive manufacturing

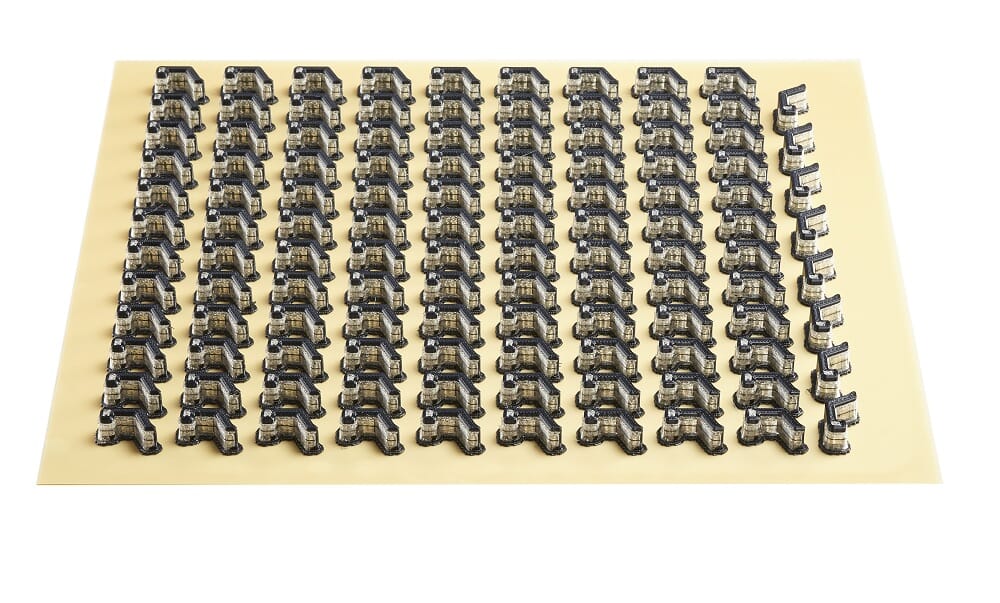

- Scalability & Flexibility: Whether you require a single prototype or large-scale batch production, our additive manufacturing capabilities allow for quick and efficient manufacturing of plastic components.

- Wide Range of Materials: We offer a wide range of thermoplastics and composite materials tailored to various applications and industry requirements, including automotive, aerospace, healthcare, and industrial manufacturing.

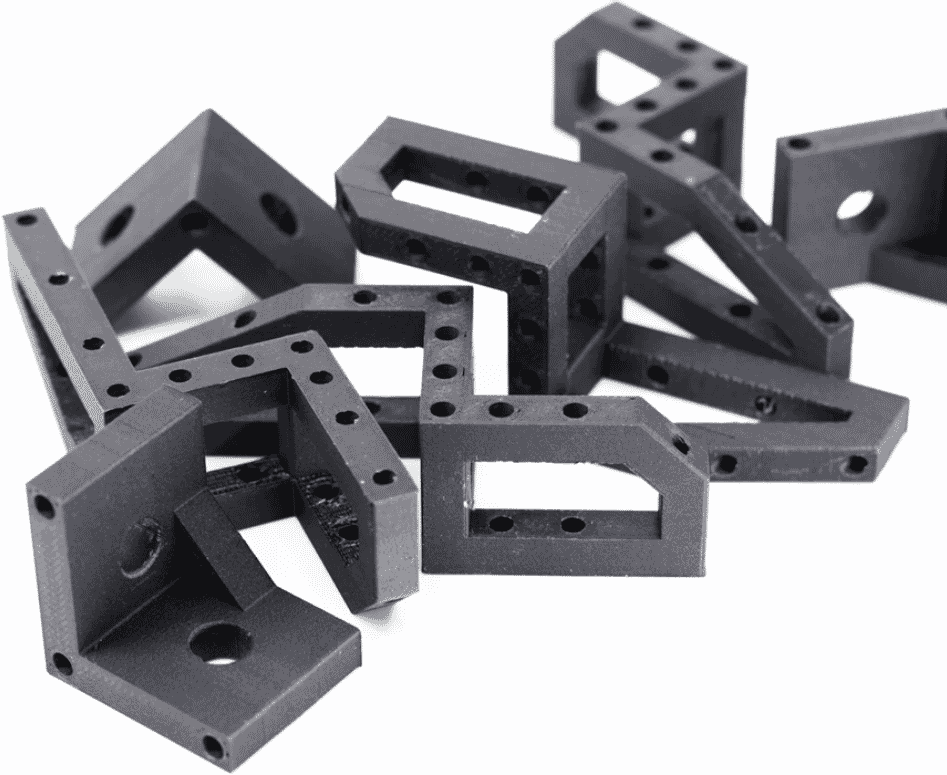

- Customizable & Complex Designs: Our advanced plastic additive manufacturing capabilities allow us to achieve intricate designs and complex geometries that would not be possible with traditional manufacturing methods.

- Cost-Effective Manufacturing: 3D printing eliminates the need for expensive tooling and reduces material waste, resulting in a much more economical production process.

Why choose AnyShape for plastic additive manufacturing?

At AnyShape, we offer much more than 3D printed plastic parts – we provide end-to-end solutions that are tailored to your specific needs. Our expertise in plastic additive manufacturing allows us to produce cutting-edge components that are specifically tailored to your application, helping you to accelerate product development, reduce costs, and improve part performance.

When you partner with AnyShape, you’ll gain access to an experienced team that can guide you through the complexities of 3D plastic printing, and provide useful recommendations on the best material and technology for your application. Get in touch to discover more about our plastic additive manufacturing capabilities.

Trusted by engineers worldwide

-

What is plastic additive manufacturing?

Plastic additive manufacturing refers to the process of creating parts such as nylon, thermoplastics, or composite plastics layer by layer through the use of SLS, FDM and CFF 3D printing technologies.

-

Which 3D printing technology is best for my project?

The ideal technology depends on several factors such as material requirements, part complexity, and the intended use of the part. Our experts can help you select the most suitable option for your project.

-

What materials can AnyShape print in plastic?

We offer a wide variety of thermoplastics, including ABS and PLA, as well as composite materials reinforced with carbon or glass fibers for added strength.

-

Can 3D-printed plastic parts be used in high-performance applications?

Yes. With the right material selection and design, 3D printed plastic parts can meet the stringent high-performance requirements for industries such as automotive, aerospace, and medical.

-

How long does it take to get my parts?

Production time depends on the complexity of the part and technology used. However, the 3D printing process is significantly faster than traditional manufacturing methods, helping to reduce lead times and streamline production.