Custom Tooling for Safran Nacelles

Custom Tooling from AnyShape helps Safran Nacelles meet tight development deadlines

Safran Nacelles is a worldwide leader in aircraft nacelles and services and has been synonymous for its engineering expertise within the aerospace industry since its formation in 2005

Therefore, when Gulfstream were looking for a nacelle development and integration partner for the development of the new Gulfstream G700N Business Jet, Safran Nacelles were the perfect partner of preference.

Short Development Times

As with many new development projects within the aerospace industry, one of the key challenges for any tooling department is to produce specific parts to fulfil certification ground and fly tests. These parts are often needed within very tight deadlines and with the development of the Rolls Royce Pearl 700 engine nacelles, this project was no exception at just 4 weeks!

Baptiste Tricot – Project Manager I Tooling at Safran comments:

” The challenge is the very short time between the nacelle parts design and the production of these new design parts for testing, we need the ability to source custom tooling very quickly that is both bespoke, high quality, accurate and cost effective”

As part of the nacelle development for the Rolls Royce Pearl 700, key objectives included:

- Weight Reduction

- Greater Fuel Efficiency

- Noise Reduction

- Reduction in manufacturing time

Precise Assembly Accuracy

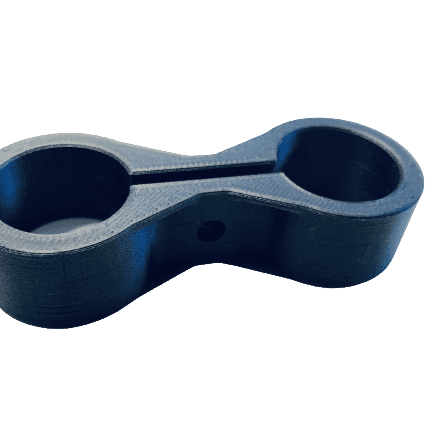

The tooling requirement for the project specifically centered around bespoke tooling used to align drilling equipment both internally and externally on the engine nacelle. Accuracy and positioning is of the utmost importance to ensure all holes created in the metal / composite parts are 90 degrees to the work surface. This is achieved by using a “Quadripod” fixture to ensure perfectly round holes and to avoid geometric dispersion (hole elongation / mishaping). Improving part accuracy and fitment was a key requisite for Safran, as more precise assembly accuracy contributes towards both increased engine performance and reduced engine noise

AnyShape Provides A Complete Solution, On Time and on Budget

As part of Safran’s procurement and supplier assessment process, AnyShape were contacted to submit quotations for the tooling work package using its state-of-the-art additive manufacturing technologies. The requirement was for custom tooling to be produced using Direct Metal Laser Sintering technology in ALSi10Mg material .

As part of the assessment process, AnyShape were evaluated along with several other (6) additive manufacturing service providers and ranked in terms of quotation time, average prices, processing time, average quality of the raw printing part, average quality of “complex” part (with gluing, machining, finishing etc), and post-processing, treatments and finishing services

What was the deciding factor for choosing AnyShape?

Baptiste Tricot explains: “AnyShape demonstrated their capacity to carry out and fulfil a complex project including machining, assembly of standard components, providing control reports, plus adding value with 3D study for optimisation and AM design engineering support. Additionally, AnyShape were able to provide us with the high quality tooling we needed, both on time and at an acceptable cost”

And Baptiste continues:

“AnyShape is the additive manufacturing supplier I use the most for tooling, as they lead the way in complex additive manufacturing and keep improving both their quality and complexity capabilities. I have worked with AnyShape for four years now and it was always a pleasure to carry out my project with them. AnyShape always meets my requirements and improves my projects which is perfect for me!